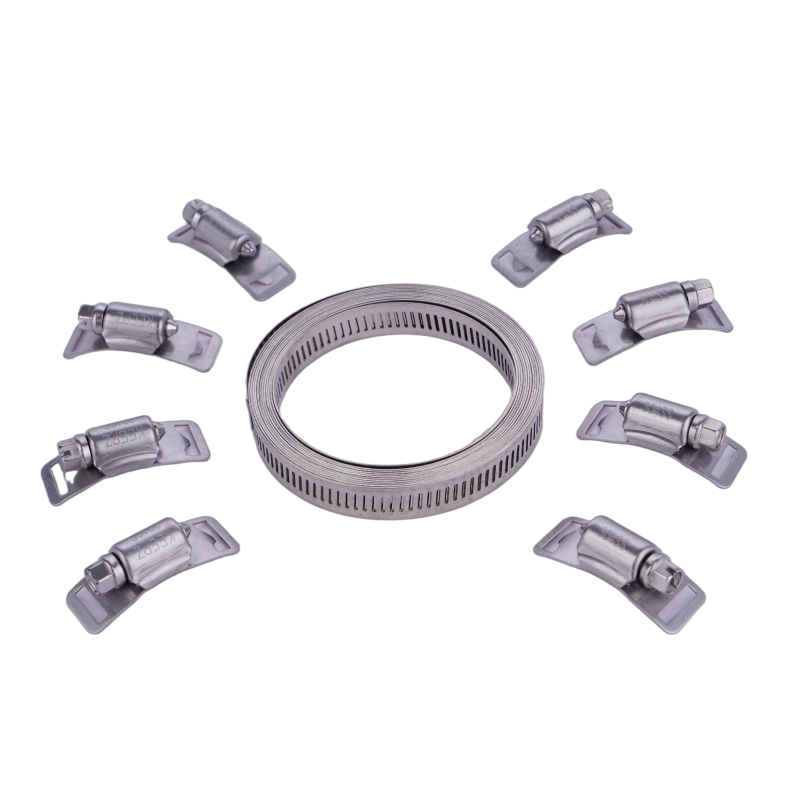

china american hose clamp manufacturer

Compliant with the SAE J1508, Type “F”

American hose clamps are worm gear driven hose clamps, widely used in construction, engineering, and home furnishing fasteners. They offer advantages such as corrosion resistance, high temperature resistance, and high strength. Structurally, the steel strip teeth of the American-style clamp are machined with through holes, enhancing the reliability of the strip-thread engagement and making the connection between the steel strip and the connected fittings more secure. Furthermore, the integrated housing design effectively prevents the housing from falling off and strengthens the clamp’s performance limits.

basic structure of american style hose clamp

screw

Multiple materials and screw slot types are available for selection

housing

The integrated housing design can prevent the housing from loosening

band

The through-hole design enhance the fimness of engagement between the band and the thread

DM13Q

Band

Stainless Steel

Housing

Stainless Steel

Hex Head

Stainless Steel

DM13B

Band

Stainless Steel

Housing

Carbon Steel or Stainless Steel

Hex Head

Carbon Steel or 400 Series Stainless Steel

DM13T

Band

Carbon Steel

Housing

Carbon Steel

Hex Head

Carbon Steel

DM14Q

Band

Stainless Steel

Housing

Stainless Steel

Hex Head

Stainless Steel

DM14B

Band

Stainless Steel

Housing

Carbon Steel or Stainless Steel

Hex Head

Carbon Steel or 400 Series Stainless Steel

DM14T

Band

Carbon Steel

Housing

Carbon Steel

Hex Head

Carbon Steel

HWKG provides following american type hose clamp

12.7mm american hose clamp

12.7mm american hose clamp

14.2mm worm drive hose clamp

american hose clamp Parameters

american hose clamp configuration table

| SPECIFICATION | MATERIAL | BAND | HOUSING | SCREW |

| DM13T/DM14T | W1 | carbon steel | carbon steel | carbon steel |

| DM13B/DM14B | W2 | 200/300 series stainless steel | carbon steel/200/300 series stainless steel | carbon steel |

| W3 | 200/300/400 series stainless steel | 200/300/400 series stainless steel | 400 series stainless steel | |

| DM13Q/DM14Q | W4 | 200/300 series stainless steel | 200/300 series stainless steel | 200/300 series stainless steel |

| W5 | 316 stainless steel | 316 stainless steel | 316 stainless steel | |

| Customization of specifications and material configurations is available based on customer requirements. The above information is for reference only and should not be considered as technical specifications. | ||||

american hose clamp specification table

| SAE Size No. | RANGE | SPECIFICATION | ||||||

| RANGE mm | RANGE in | DM13Q | DM14Q | DM13B | DM14B | DM13T | DM14T | |

| 6 | 11-20 | 7/16″-25/32″ | • | • | • | • | • | • |

| 8 | 13-23 | 1/2″-29/32″ | • | • | • | • | • | • |

| 10 | 14-27 | 9/16″-1 1/16″ | • | • | • | • | • | • |

| – | 17-32 | 11/16″-1 1/4″ | • | • | • | • | • | • |

| 12 | 18-32 | 23/32″-1 1/4″ | • | • | • | • | • | • |

| – | 19-38 | 3/4″-1 1/2″ | • | • | • | • | • | • |

| 16 | 21-38 | 13/16″-1 1/2″ | • | • | • | • | • | • |

| 20 | 21-44 | 13/16″-1 3/4″ | • | • | • | • | • | • |

| – | 21-45 | 13/16″-1 25/32″ | • | • | • | • | • | • |

| 27-50 | 1 1/16″-1 31/32″ | • | • | • | • | • | • | |

| 24 | 27-51 | 1 1/16″-2″ | • | • | • | • | • | • |

| 28 | 33-57 | 1 5/16″-2 1/4″ | • | • | • | • | • | • |

| – | 39-64 | 1 17/32″-2 1/2″ | • | • | • | • | • | • |

| 32 | 40-64 | 1 9/16″-2 1/2″ | • | • | • | • | • | • |

| – | 45-70 | 1 25/32″-2 3/4″ | • | • | • | • | • | • |

| 36 | 46-70 | 1 13/16″-2 3/4″ | • | • | • | • | • | • |

| 40 | 52-76 | 2 1/16″-3″ | • | • | • | • | • | • |

| – | 58-83 | 2 9/32″-3 1/4″ | • | • | • | • | • | • |

| 44 | 59-83 | 2 5/16″-3 1/4″ | • | • | • | • | • | • |

| 48 | 65-89 | 2 9/16″-3 1/2″ | • | • | • | • | • | • |

| 52 | 71-95 | 2 13/16″-3 3/4″ | • | • | • | • | • | • |

| 56 | 78-102 | 3 1/16″-4″ | • | • | • | • | • | • |

| 60 | 84-108 | 3 5/16″-4 1/4″ | • | • | • | • | • | • |

| 64 | 90-114 | 3 9/16″-4 1/2″ | • | • | • | • | • | • |

| 72 | 103-127 | 4 1/16″-5″ | • | • | • | • | ||

| 80 | 117-140 | 4 5/8″-5 1/2″ | • | • | • | • | ||

| 88 | 130-152 | 5 1/8″-6″ | • | • | • | • | ||

| 96 | 141-165 | 5 9/16″-6 1/2″ | • | • | • | • | ||

| 104 | 157-178 | 6 3/16″-7″ | • | • | • | • | ||