china flexible pipe coupling supplier

Compliant with the CUPC, ASTM C1173

A flexible pipe coupling is a versatile connector used to join two pipe sections while allowing for movement, vibration absorption, and minor misalignment. Unlike rigid couplings, flexible couplings use durable elastomeric materials to allow controlled flexibility, helping to prevent leaks and reduce system stress. It ensures a secure, leak-free connection across plumbing, drainage, and industrial systems.

With over 20 years of manufacturing experience, Hengwei’s HWKG® brand delivers reliable, high-quality flexible couplings trusted across global plumbing and industrial applications. The following sections will introduce HWKG’s advantages, features, and wide-ranging uses in greater detail.

what Makes hwkg different

20+ years of manufacturing expertise and large-scale production

strong R&D Power — 2 invention patents and 20+ utility patents

certified quality and automated inspection for zero defects

hwkg flexible pipe coupling technical specifications

- Installation torque: 60 inch Ibs

- Maximum test pressure: 4.3 PSI (29.6KPA)

- Maximum operating temperature: 140°F non-consistent

- Minimum operating temperature: -30°F

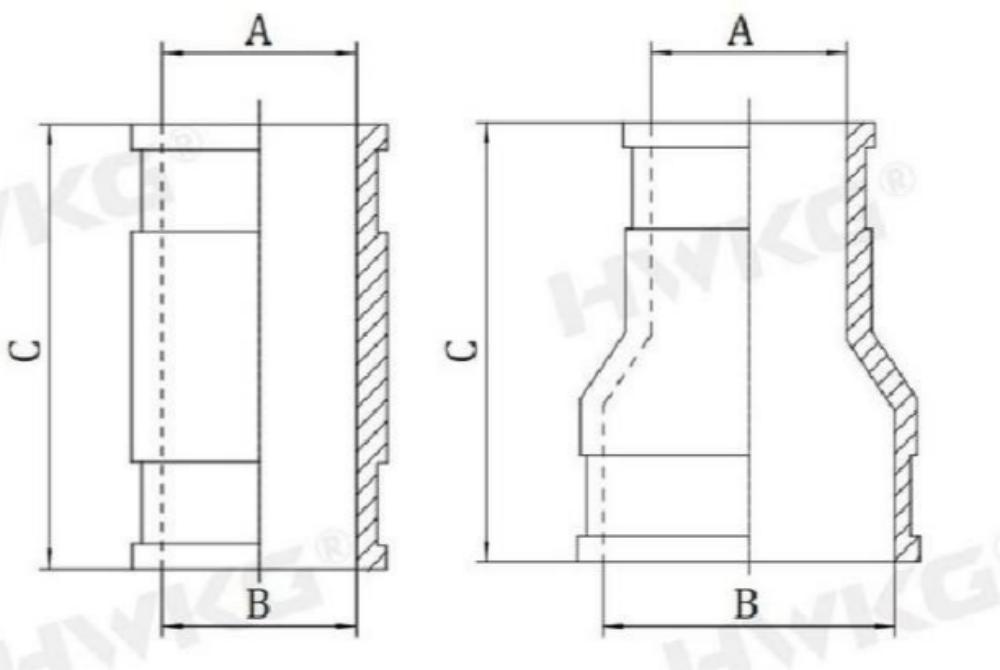

flexible pipe coupling specification table

| PART NO. | A | B | C | ||||

| mm | in | mm | in | mm | |||

| HW-T075 | 1.06 | 27 | 1.06 | 27 | 2.36 | 60 | |

| HW-T100 | 1.3 | 33 | 1.3 | 33 | 2.36 | 60 | |

| HW-T125 | 1.57 | 40 | 1.57 | 40 | 3.46 | 88 | |

| HW-T150 | 1.89 | 48 | 1.89 | 48 | 3.46 | 88 | |

| HW-T22 | 2.36 | 60 | 2.36 | 60 | 3.46 | 88 | |

| HW-T33 | 3.43 | 87 | 3.43 | 87 | 3.98 | 101 | |

| HW-T44 | 4.37 | 11 | 4.37 | 111 | 3.98 | 101 | |

| HW-T55 | 5.51 | 140 | 5.51 | 140 | 3.98 | 101 | |

| HW-T66 | 6.57 | 167 | 6.57 | 167 | 5.75 | 146 | |

| HW-T88 | 8.62 | 219 | 8.62 | 219 | 5.98 | 152 | |

| HW-DT150/125 | 1.57 | 40 | 1.89 | 48 | 3.46 | 88 | |

| HW-DT215 | 1.89 | 48 | 2.4 | 61 | 3.46 | 88 | |

| HW-DT32 | 2.4 | 61 | 3.52 | 89.5 | 3.98 | 101 | |

| HW-DT42 | 2.36 | 60 | 4.41 | 112 | 4.02 | 102 | |

| HW-DT43 | 3.5 | 89 | 4.45 | 113 | 3.98 | 101 | |

| HW-DT53 | 3.43 | 87 | 5.43 | 138 | 3.98 | 101 | |

| HW-DT54 | 4.25 | 108 | 5.55 | 141 | 4.02 | 102 | |

| HW-DT64 | 4.45 | 113 | 6.61 | 168 | 5.75 | 146 | |

| HW-DT65 | 5.55 | 141 | 6.38 | 162 | 5.75 | 146 | |

| HW-DT86 | 6.22 | 158 | 8.5 | 216 | 5.98 | 152 | |

flexible coupling key features

accommodates misalignment

Flexible rubber coupler is reducing stress from temperature shifts, vibration, and ground movement. It ensures extends pipeline service life through misalignment accommodation.

vibration and shock absorption

Rubber pipe connectors outperform metal couplings in vibration damping, impact absorption, and noise control. It is ideal for systems needing flexibility or minor alignment adjustment.

simple installation and maintenance

Flexible coupling allow quick, tool-free installation and maintenance, connecting pipes of various materials and sizes without welding. Fully compliant with ASTM and CSA standards.

durability

The reinforced rubber and stainless-steel bands provide lasting strength, maintaining secure connections even under pressure fluctuations and harsh environments.

leak-proof seal

Precisely engineered for uniform compression, flex coupler ensures watertight sealing under pressure. Resistant to chemicals, UV, and microbial damage.

universal compatibility

Our flexible rubber coupler connect PVC, cast iron, steel, or copper pipes securely. Their flexible design ensures universal compliance, adaptability, and reliability across all piping systems.

common types of flexible couplings for pipes

Flexible pipe couplings can be classified into six main categories based on their structure and function. As a professional manufacturer, HWKG offers a complete range of these products and provides expert technical guidance to help customers choose the right solution for every piping application.

flexible straight coupling

-Structure Features: Made of a strong rubber sleeve and stainless-steel clamps, it connects two pipes of the same diameter securely.

-Main Functions: Compensates for slight misalignment, absorbs vibration, and prevents leakage caused by ground movement or temperature changes.

-Typical Applications: Mainly used in drainage pipes of bathrooms, kitchens, etc. where quick installation and reliable sealing are essential.

rubber reducer coupling

-Structure Features: Built with flexible rubber and corrosion-resistant steel clamps, designed to join pipes of different diameters or materials.

-Main Functions: Provides a smooth transition between various pipe sizes, reducing stress and maintaining a tight seal even under pressure or vibration.

-Typical Applications: Commonly used in pipe repair, retrofitting, or upgrades in industrial, irrigation, and sewage systems requiring size adaptation.

flexible elbow coupling

-Structure Features: Designed with a curved, flexible body combining rubber and stainless steel to support angled or directional connections.

-Main Functions: Allows smooth directional changes in pipelines while absorbing vibration and reducing stress compared with rigid fittings.

-Typical Applications: Suitable for HVAC systems, irrigation lines, and mechanical piping where flexible alignment and noise reduction are required.

flexible pipe cap

-Structure Features: A closed-end rubber cap reinforced with stainless-steel bands for secure, corrosion-resistant sealing.

-Main Functions: Used to temporarily or permanently close the end of a pipe, preventing debris, leaks, or contamination.

-Typical Applications: Commonly applied in drainage, plumbing maintenance, and wastewater systems during testing, repair, or unused pipe closure.

no-hub coupling

-Structure Features: Composed of a durable rubber sleeve and a stainless-steel shield secured by multiple clamps for maximum strength.

-Main Functions: Connects hubless cast iron pipes, maintains alignment, and prevents leaks under high pressure and vibration.

-Typical Applications: Widely applied in building drainage, vent systems, and wastewater piping where compact, high-strength joints are needed.

shielded transition coupling

-Structure Features: Features a reinforced rubber sleeve covered by a stainless-steel outer shield that provides extra rigidity and compression stability.

-Main Functions: Connects pipes made from different materials or wall thicknesses, ensuring structural integrity and long-lasting sealing performance.

-Typical Applications: Used in underground pipelines, high-pressure drainage, and industrial fluid systems demanding durability and corrosion resistance.

flexible pipe coupling material composition

A flexible pipe coupling typically consists of two main components: a gasket and stainless steel hose clamps. The gasket serves as the sealing body, while the clamps provide external reinforcement and tightening force. Common gasket materials include PVC and rubber, each offering distinct advantages for different piping conditions.

flexible pvc coupling

Flexible PVC couplings are made from soft yet durable polyvinyl chloride, offering excellent flexibility and corrosion resistance. The smooth inner surface ensures a reliable seal and easy fit with PVC, ABS, or cast-iron pipes. Their lightweight design allows quick installation without tools or adhesives. These couplings perform best in residential drainage, irrigation, and light-duty plumbing systems, where moderate pressure and clean-water flow are required.

flexible rubber coupling

Flexible rubber couplings are typically manufactured from high-grade EPDM or NBR rubber, providing exceptional elasticity, temperature tolerance, and chemical stability. They maintain a watertight seal under pressure fluctuations and efficiently absorb vibration and ground movement. These couplings are particularly suitable for industrial wastewater, HVAC, and underground sewer systems, where pipes experience frequent vibration, high flow rates, or chemical exposure.

stainless steel clamp

Stainless steel clamp, commonly made from 304 or 316-grade stainless steel. hwkg provides stainless steel clamps in 200 series, 300 series, 400 series and carbon steel. They deliver uniform compression across the joint, preventing infiltration and exfiltration even under high internal pressures. Corrosion-resistant and rustproof, these clamps remain stable in marine, industrial, and high-moisture environments where long-term durability is critical.

applications of flex pipe coupler

residential plumbing systems

Flexible pipe couplers absorb pipe shifts from ground or temperature changes. They create secure, leak-free joints between materials like copper, PVC, and steel without requiring perfect alignment. They reduce noise, ease installation, and enhance reliability in residential plumbing systems.

wastewater and sewage management

Flexible couplers offer leak-proof, corrosion-resistant connections in wastewater systems, linking PVC, HDPE, or concrete pipes. They absorb soil and load stress, prevent leaks, and ensure durable, low-maintenance performance in municipal and industrial sewage applications.

industrial process piping

Flexible couplers handle fluids, gases, and chemicals in industrial pipelines, absorbing vibration and thermal expansion. Compatible with steel, fiberglass, or alloy pipes, they prevent leaks, reduce mechanical strain, and simplify maintenance in chemical plants and power stations.

irrigation and agricultural systems

Flexible couplers connect PVC, aluminum, or polyethylene pipes in irrigation systems, adapting to uneven terrain. Resistant to UV, fertilizers, and abrasion, they prevent leaks, maintain pressure, and ensure durable, efficient water distribution in agriculture.

HVAC and mechanical systems

Flexible couplers connect HVAC pipes, absorbing vibration and managing thermal expansion. They reduce noise from from compressors, fans, and pumps, simplify installation in tight spaces, and enhance energy efficiency and equipment lifespan in commercial and industrial systems.

fire protection systems

Flexible couplers ensure reliable water flow in fire suppression systems, joining sprinkler and hydrant lines. They withstand seismic activity, adapt around obstacles, allow easy maintenance, and maintain compliance, providing dependable performance in commercial and high-rise buildings.

flexible pipe coupling installation instructions

- Clean the Pipe Ends – Ensure that both pipe surfaces are smooth and free of debris, oil, or rust.

- Position the flexible pipe coupling – Slide the coupling over one pipe end, then align the second pipe.

- Center the Coupling – Adjust the coupling so it evenly overlaps both pipe ends.

- Tighten the stainless steel pipe clamp – Using a torque wrench or screwdriver, tighten the stainless-steel clamps evenly to create a firm, leak-free connection.

- Inspect the Seal – Check the joint to ensure a uniform seal and proper alignment before system pressurization.

FAQ about flexible pipe coupling

can you use flexible coupling in a drain pipe?

Yes, you can use a flexible coupling in a drain pipe, but it’s essential to choose one rated for the specific application and compliant with local plumbing codes. The correct coupling ensures a secure, watertight connection between different pipe materials, while maintaining durability and leak resistance under varying conditions. Always verify compatibility with pipe size, material, and environmental requirements before installation to guarantee long-term reliability and code compliance.

If you encounter any problems, you can contact our experts to get professional solutions.

how much pressure can a flexible coupling hold?

The pressure capacity of a flexible coupling depends on its design and intended use.

For example, HWKG flexible pipe couplings are tested to a maximum pressure of 4.3 PSI (29.6 kPa), ensuring reliable sealing performance under normal drainage, wastewater, and low-pressure piping applications.

While these couplings are not designed for high-pressure systems, they provide excellent leak protection, flexibility, and durability in gravity-flow or low-pressure installations where slight movement or misalignment may occur. Always confirm the pressure rating before installation to ensure proper performance and safety.