heavy duty hose clamp manufacturer and supplier

Compliant with the DIN 3017-3

A heavy duty clamp, also known as a single bolt hose clamp, is a robust welded clamp designed for high-pressure hose or pipe connections. It delivers exceptional strength and sealing performance, ensuring a secure and long-lasting joint even in demanding industrial or automotive applications.

We offer a complete range of heavy duty hose clamps with customizable sizes and materials to fit various hose and pipe dimensions. Each heavy duty clamp is precision-engineered using advanced manufacturing technology, delivering superior durability, consistent clamping force, and long-term reliability even in the most demanding environments.

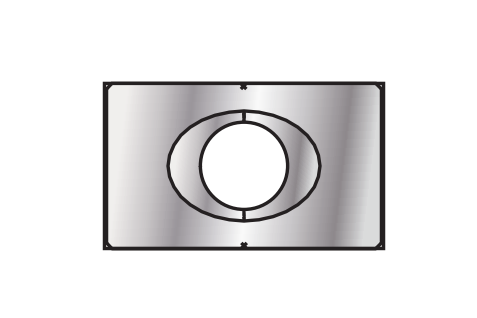

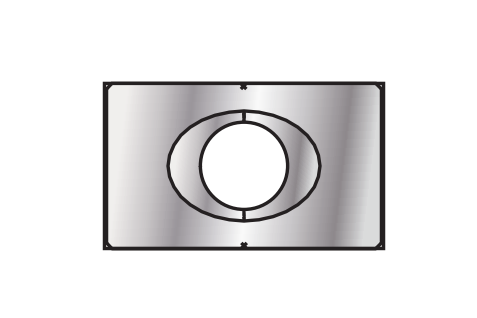

Components of heavy duty hose clamps

Surface galvanized, accessories tested in neutral salt spray for no less than 24/48/72 hours without red rust.

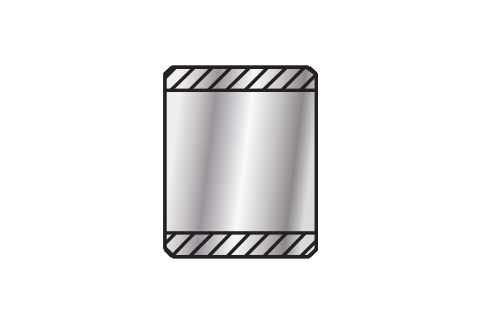

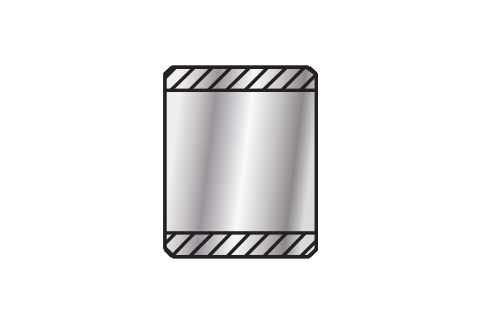

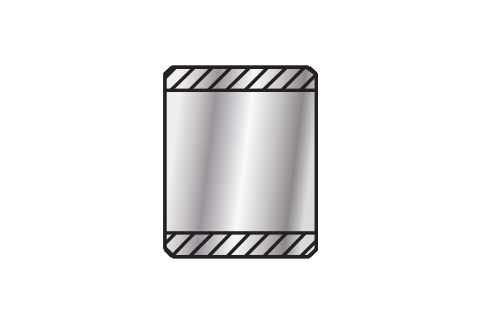

Bushing

Convenient in stallation and protection of steel band from damage

Bolt

High-strength and highlyreliable bolt

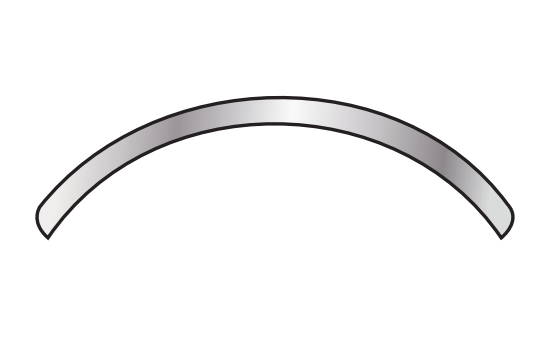

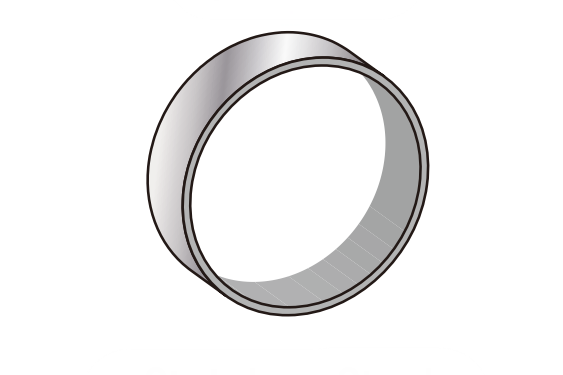

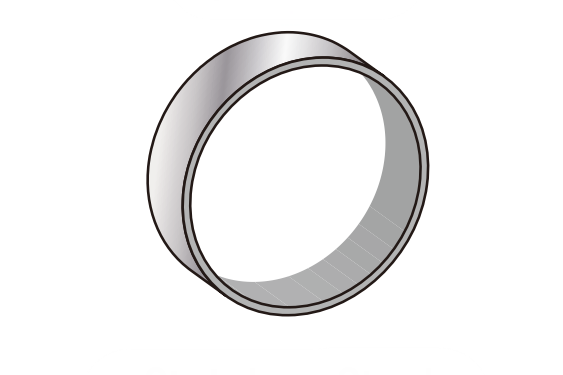

Band

One-piece edge boneted steel band for protecting rubber or steel tubing

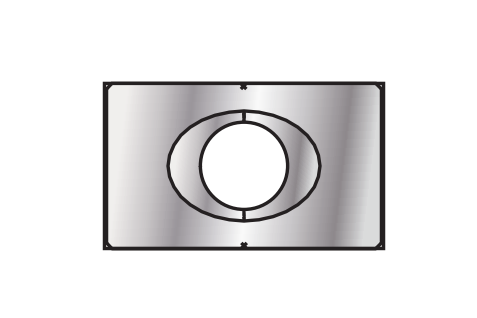

Trunnion

Effective fastening bolt with dependable strength

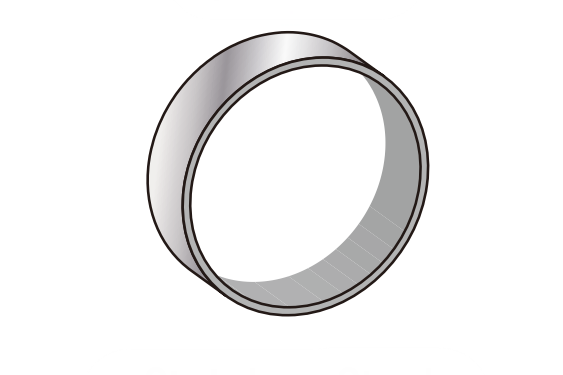

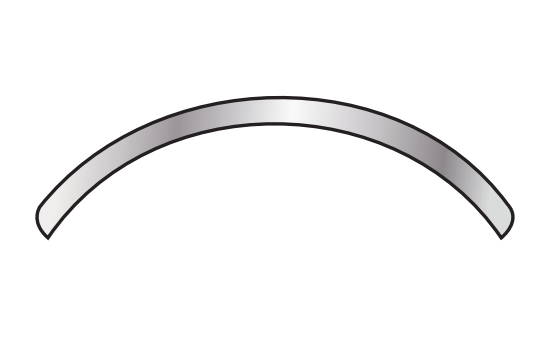

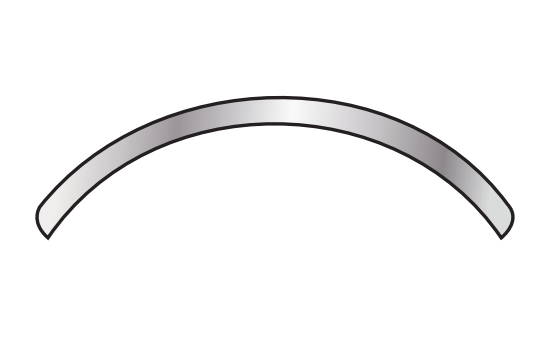

Bridge

Seamless sealing structure

Disc Spring

Continuously providing torque compensation under varying temperatures

HWKG models of heavy duty hose clamp

DT-Q

Band

Stainless Steel

Bridge

Stainless Steel

Trunnion

Stainless Steel

Bushing

Stainless Steel

Bolt

Stainless Steel

DT-Bt

Band

Stainless Steel

Bridge

Stainless Steel

Trunnion

Carbon Steel

Bushing

Carbon Steel

Bolt

Carbon Steel

DT-T

Band

Carbon Steel

Bridge

Carbon Steel

Trunnion

Carbon Steel

Bushing

Carbon Steel

Bolt

Carbon Steel

HWKG Heavy Duty Hose Clamp Configuration Table

| SPECIFICATION | MATERIAL | BAND | BRIDGE | TRUNNION | BUSHING | BOLT |

|---|---|---|---|---|---|---|

| DTxxT | W1 | carbon steel | carbon steel | carbon steel | carbon steel | carbon steel |

| DTxxBt | W2 | 200/300 series stainless steel | 200/300 series stainless steel | carbon steel | carbon steel | carbon steel |

| DTxxQ | W4 | 304 stainless steel | 304 stainless steel | 304 stainless steel | 304 stainless steel | 304 stainless steel |

| W5 | 316 stainless steel | 316 stainless steel | 316 stainless steel | 316 stainless steel | 316 stainless steel | |

| Customization of specifications and material configurations is available based on customer requirements. The above information is for reference only and should not be considered as technical specifications. | ||||||

HWKG Heavy Duty Hose Clamp Specification Table

| RANGE | SPECIFICATION | BAND WIDTH | BOLT | |||

|---|---|---|---|---|---|---|

| RANGE mm | RANGE IN | DTxxQ | DTxxBt | DTxxT | ||

| 17–19 | 11/16″–3/4″ | ● | ● | ● | 18 | M5×40 |

| 19–21 | 3/4″–13/16″ | ● | ● | ● | ||

| 20–22 | 25/32″–7/8″ | ● | ● | ● | ||

| 21–23 | 13/16″–29/32″ | ● | ● | ● | ||

| 23–25 | 29/32″–1″ | ● | ● | ● | ||

| 26–28 | 1 1/32″–1 3/32″ | ● | ● | ● | ||

| 27–29 | 1 1/16″–1 5/32″ | ● | ● | ● | 20 | M6×50 |

| 29–31 | 1 5/32″–1 1/8″ | ● | ● | ● | ||

| 32–35 | 1 1/4″–1 3/8″ | ● | ● | ● | ||

| 34–37 | 1 11/32″–1 15/32″ | ● | ● | ● | ||

| 36–39 | 1 13/32″–1 17/32″ | ● | ● | ● | ||

| 38–41 | 1 1/2″–1 5/8″ | ● | ● | ● | ||

| 40–43 | 1 9/16″–1 11/16″ | ● | ● | ● | 22 | M6×60 |

| 43–46 | 1 11/16″–1 13/16″ | ● | ● | ● | ||

| 44–47 | 1 3/4″–1 27/32″ | ● | ● | ● | ||

| 48–51 | 1 7/8″–2″ | ● | ● | ● | ||

| 52–55 | 2 1/16″–2 5/32″ | ● | ● | ● | ||

| 56–59 | 2 3/16″–2 5/16″ | ● | ● | ● | ||

| 60–63 | 2 3/8″–2 15/32″ | ● | ● | ● | ||

| 64–67 | 2 1/2″–2 5/8″ | ● | ● | ● | ||

| RANGE | SPECIFICATION | BAND WIDTH | BOLT | |||

|---|---|---|---|---|---|---|

| RANGE mm | RANGE IN | DTxxQ | DTxxBt | DTxxT | ||

| 65–70 | 2 9/16″–2 3/4″ | ● | ● | ● | 24 | M8×75 |

| 68–73 | 2 11/16″–2 7/8″ | ● | ● | ● | ||

| 74–79 | 2 29/32″–3 1/8″ | ● | ● | ● | ||

| 80–85 | 3 5/32″–3 11/32″ | ● | ● | ● | ||

| 86–91 | 3 3/8″–3 19/32″ | ● | ● | ● | ||

| 92–97 | 3 5/8″–3 13/18″ | ● | ● | ● | ||

| 98–103 | 3 7/8″–4 1/16″ | ● | ● | ● | ||

| 104–112 | 4 3/32″–4 13/32″ | ● | ● | ● | 24 | M8×80 |

| 113–121 | 4 7/16″–4 3/4″ | ● | ● | ● | ||

| 122–130 | 4 13/16″–5 1/8″ | ● | ● | ● | ||

| 131–139 | 5 5/32″–5 15/32″ | ● | ● | ● | 26 | M10×100 |

| 140–148 | 5 1/2″–5 53/64″ | ● | ● | ● | ||

| 149–161 | 5 7/8″–6 11/32″ | ● | ● | ● | 26 | M10×110 |

| 162–174 | 6 3/8″–6 27/32″ | ● | ● | ● | ||

| 175–187 | 6 29/32″–7 1/4″ | ● | ● | ● | ||

| 188–200 | 7 13/32″–7 7/8″ | ● | ● | ● | ||

| 201–213 | 7 29/32″–8 13/32″ | ● | ● | ● | ||

| 214–226 | 8 7/16″–8 29/32″ | ● | ● | ● | ||

| 227–239 | 8 15/16″–9 13/32″ | ● | ● | ● | ||

| 240–252 | 9 7/16″–9 59/64″ | ● | ● | ● | ||

HWKG provides following heavy duty hose clamps

Single-headed heavy duty padded clamp

Single-head heavy duty clamp with spring pad

Single-head clamp with bracket

Single-headed clamp with rubber strip

Key features of heavy duty clamp

High Clamping Force

Each heavy duty hose clamp delivers strong and consistent clamping pressure, ensuring a tight, leak-proof seal even under high pressure or vibration. This makes it ideal for reinforced hoses and demanding industrial systems.

Durable Stainless Steel Construction

Manufactured from high-grade stainless steel such as 304 or 316, the heavy duty clamp offers excellent resistance to rust, corrosion, and oxidation, providing long-lasting reliability in marine, chemical, or outdoor environments.

Single Bolt Design for Easy Installation

Featuring a practical single bolt structure, this heavy duty hose clamp allows for quick installation and easy adjustment. The welded design maintains strength while simplifying assembly compared to multi-bolt types.

Customizable Sizes and Applications

Available in a wide range of diameters and bandwidths, the heavy duty hose clamp can be customized for different hose or pipe dimensions. It’s widely used across automotive, marine, and industrial applications where reliable performance is essential.

Sturdy Screw Mechanism

Equipped with a robust hex or slotted head screw, the heavy duty bolt clamp provides high torque capability and secure tightening. Zinc-plated or stainless-steel screws enhance mechanical strength and durability.

Wide Band and Smooth Inner Surface

The broad stainless-steel band ensures even pressure distribution to prevent hose deformation, while the smooth or embossed inner surface increases grip without damaging the hose material.

Materials used in heavy duty bolt clamps

HWKG heavy duty clamps are made from carefully selected high-quality materials, different materials can be combined according to specific working conditions to achieve optimal performance.

200 Series Stainless Steel Heavy Duty Clamp

Our 200 series stainless steel heavy duty clamp provides an economical yet dependable solution. It delivers good tensile strength, oxidation resistance, and surface hardness suitable for general industrial use. With proper maintenance, 200 series clamps offer stable performance and corrosion resistance in non-extreme conditions.

Heavy Duty 304 Stainless Steel Hose Clamp

The heavy duty 304 stainless steel hose clamp is a versatile option widely used across industrial and automotive systems. Known for its excellent corrosion resistance and strength, 304 stainless steel provides reliable performance in humid or mildly corrosive environments. It maintains consistent clamping force and a long service life, making it a trusted choice for general-purpose applications.

Heavy Duty 316 Stainless Steel Hose Clamp

For environments exposed to high salinity or aggressive chemicals, the heavy duty 316 stainless steel hose clamp offers outstanding durability. With added molybdenum in its composition, 316 stainless steel enhances resistance to pitting, oxidation, and chloride corrosion. It is ideal for marine, chemical processing, and outdoor applications where superior protection is required.

Carbon Steel Clamp With Single Bolt

The carbon steel clamp with single bolt design is known for its high mechanical strength and cost efficiency. Featuring a robust welded structure and protective surface treatment such as zinc plating, it resists wear and maintains firm clamping force under pressure. This type of heavy duty bolt clamp is suitable for applications where strength and affordability are both important.

Application of single bolt clamp

HWKG heavy duty hose clamps are engineered to perform reliably across a wide range of industrial, automotive, and marine applications.

High-Pressure Fluid Transfer Systems

Heavy duty hose clamps are ideal for pipelines that convey compressed air, hydraulic oil, or pressurized water. Their reinforced band and high-torque bolt ensure reliable sealing even when exposed to fluctuating pressure or pulsation.

Marine and Offshore Equipment

Designed for durability in corrosive environments, heavy duty stainless steel hose clamps perform reliably in marine engines, ballast water lines, and deck machinery exposed to seawater and humidity.

Agricultural and Irrigation Systems

From irrigation manifolds to fertilizer lines, heavy duty hose clamps withstand outdoor exposure, temperature shifts, and continuous water pressure cycles without loosening or corrosion.

Construction and Mining Machinery

For equipment operating under dust, vibration, and high mechanical stress, these clamps secure fuel hoses, air ducts, and hydraulic lines, maintaining consistent performance in demanding environments.

Turbocharger and Exhaust Connections

In automotive and heavy machinery applications, heavy duty hose clamps secure joints in turbocharger outlets, intercooler piping, and exhaust systems, where vibration and heat expansion demand superior stability.

The Difference Between Heavy Duty Clamp and Worm Drive Hose Clamp

the serve to secure hoses onto fittings, but differ in structure, strength, and applications.

Heavy Duty Hose Clamps

HWKG heavy duty clamps feature a solid stainless steel band combined with a robust single-bolt design. This structure delivers uniform compression and a much stronger clamping force, ideal for demanding environments such as trucks, machinery, and industrial pipelines. Their thicker, wider bands and reinforced bridges allow them to maintain a secure seal under high pressure and vibration.

Worm Drive Hose Clamps

Worm drive clamps, on the other hand, use a screw thread and perforated band to tighten the connection. They are lightweight, easy to install, and cost-effective, making them popular for general-purpose and low-pressure applications such as plumbing, garden hoses, and small equipment. While not as strong as heavy duty clamps, their flexibility and simplicity make them a convenient option for everyday use.

Why choose HWKG as your heavy duty clamp solution?

Choosing HWKG guarantees sincere service, superior quality, and technological innovation.

Certified Quality Management

HWKG follows international standards with certifications like ISO9001, IATF16949, ISO14001, and ISO45001, ensuring stable quality and environmental care.

Strong R&D and Innovation

With 2 invention and 20+ utility patents, HWKG keeps improving design and production technology to deliver reliable and competitive products.

Recognized Industry Excellence

HWKG has earned national honors such as “High-Tech Enterprise”, “Integrity Enterprise”, and “Advanced Enterprise”, reflecting trusted industry leadership.

Efficient Management System

Using an ERP system for over ten years, HWKG maintains precise control of production and logistics to ensure efficient, on-time delivery.

Heavy Duty Hose Clamp FAQ Guide

What’s the difference between heavy duty clamps and regular hose clamps?

HWKG heavy duty hose clamps are built with a wider and thicker stainless-steel band, a reinforced bridge, and a high-strength screw mechanism. Compared with regular hose clamps, these features provide greater clamping force, higher resistance to vibration, and better sealing under pressure. This makes our heavy duty clamps ideal for large-diameter hoses and demanding industrial or automotive applications.

Are heavy duty hose clamps suitable for high-pressure applications?

Yes. HWKG heavy duty hose clamps are specifically engineered for high-pressure and high-vibration environments. Their reinforced band structure and strong bolted mechanism ensure a secure and leak-proof seal even under demanding operating conditions. They are commonly used in industrial pipelines, heavy trucks, turbocharger systems, and other applications requiring reliable clamping performance.

What size range is available for HWKG heavy duty hose clamps?

HWKG offers a wide selection of heavy duty hose clamps with diameters ranging from 17mm to 252mm, suitable for various hose and pipe dimensions.