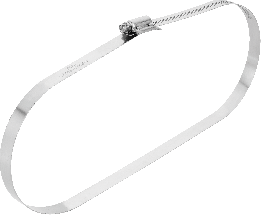

heavy duty worm gear clamp supplier

Compliant with the SAE J1508

This type of clamp is belong to worn driven structure clamp with more higher torque performance,suitable for application with high internal pressure and thick walls.

A heavy-duty worm gear clamp is a stronger, reinforced version of a standard hose clamp. It uses a worm-gear screw and a thicker stainless-steel band to provide higher torque, better sealing, and improved resistance to pressure and corrosion. It’s commonly used in industrial, automotive, and plumbing applications where a secure, durable hold is required.

basic structure of heavy duty worm clamp

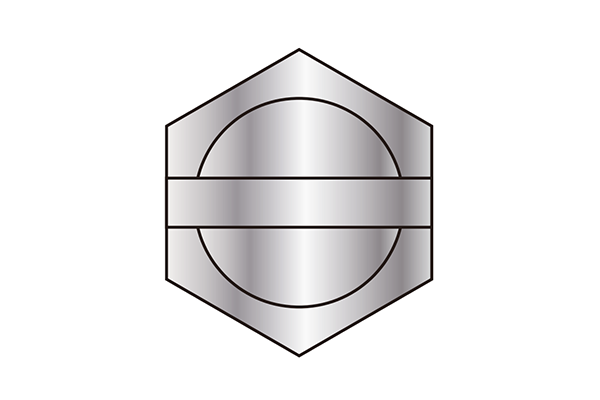

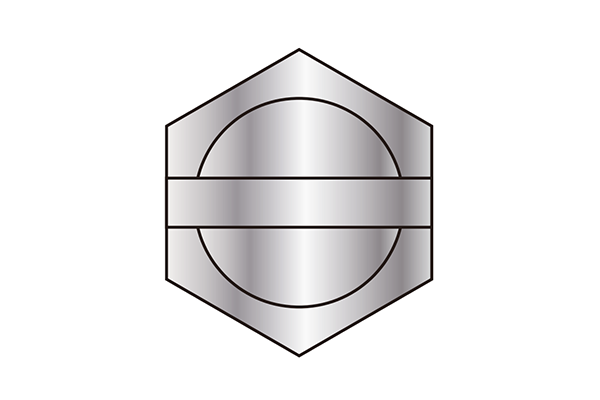

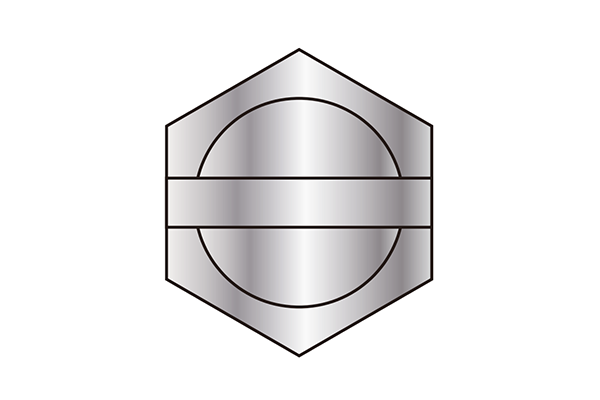

screw

External hexagon screw, multiple materials, head sizes, and screw slot types are available for selection

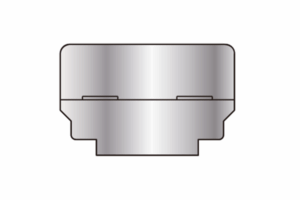

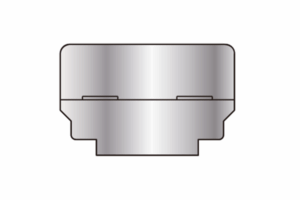

upper cover/base

The split housing design maximizes the meshing of teeth and threads,enhancing performance

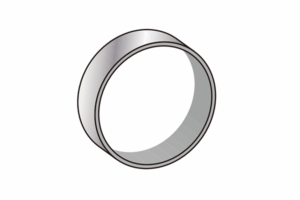

band

Crescent-shaped toothed holes with rounded transitions effectively imprve thread meshing smoothness,while maximizing reduction of load-induction of load-induced stress cracking

KG13Q

Band

Stainless Steel

Upper Cover/Base

Stainless Steel

Hex Head

Stainless Steel

KG13B

Band

Stainless Steel

Upper Cover/Base

Stainless Steel

Hex Head

carbon steel or 400 series Stainless Steel

KG14Q

Band

Stainless Steel

Upper Cover/Base

Stainless Steel

Hex Head

Stainless Steel

KG14B

Band

Stainless Steel

Upper Cover/Base

Stainless Steel

Hex Head

carbon steel or Stainless Steel

KG16Q

Band

Stainless Steel

Upper Cover/Base

Stainless Steel

Hex Head

Stainless Steel

HWKG provides following heavy duty worm gear clamp

snap lock clamp with sleeves

Snap lock Bushing clamp

Snap lock assembly clamp

snap lock V-groove clamp

Oval-shaped snap lock clamp

heavy duty worm gear clamp configuration table

| SPECIFICATION | MATERIAL | BAND | HOUSING | SCREW |

|---|---|---|---|---|

| KG13B / KG14B | W2 | 200/300 series stainless steel | 200/300 series stainless steel | carbon steel |

| W3 | 200/300/400 series stainless steel | 200/300/400 series stainless steel | 400 series stainless steel | |

| KG13Q / KG14Q / KG16Q | W4 | 200/300 series stainless steel | 200/300 series stainless steel | 200/300 series stainless steel |

| W5 | 316 stainless steel | 316 stainless steel | 316 stainless steel | |

| Customization of specifications and material configurations is available based on customer requirements. The above information is for reference only and should not be considered as technical specifications | ||||

heavy duty worm gear clamp specification table

| SAE Size No. | RANGE | SPECIFICATION | ||||

|---|---|---|---|---|---|---|

| Range mm | Range in | KG13Q | KG13B | KG14Q | KG14B | |

| – | 11-20 | 7/16″-25/32″ | ● | ● | ● | ● |

| – | 13-23 | 1/2″-29/32″ | ● | ● | ● | ● |

| 10 | 14-27 | 9/16″-1 1/16″ | ● | ● | ● | ● |

| 12 | 18-32 | 11/16″-1 1/4″ | ● | ● | ● | ● |

| 16 | 21-38 | 13/16″-1 1/2″ | ● | ● | ● | ● |

| 20 | 21-44 | 13/16″-1 3/4″ | ● | ● | ● | ● |

| 24 | 27-51 | 1 1/16″-2″ | ● | ● | ● | ● |

| 28 | 33-57 | 1 5/16″-2 1/4″ | ● | ● | ● | ● |

| 32 | 40-64 | 1 9/16″-2 1/2″ | ● | ● | ● | ● |

| 36 | 46-70 | 1 13/16″-2 3/4″ | ● | ● | ● | ● |

| 40 | 52-76 | 2 1/16″-3″ | ● | ● | ● | ● |

| 44 | 59-83 | 2 5/16″-3 1/4″ | ● | ● | ● | ● |

| 48 | 65-89 | 2 9/16″-3 1/2″ | ● | ● | ● | ● |

| 52 | 71-95 | 2 13/16″-3 3/4″ | ● | ● | ● | ● |

| 56 | 78-102 | 3 1/16″-4″ | ● | ● | ● | ● |

| 60 | 84-108 | 3 5/16″-4 1/4″ | ● | ● | ● | ● |

| 64 | 90-114 | 3 9/16″-4 1/2″ | ● | ● | ● | ● |

| 72 | 103-127 | 4 1/16″-5″ | ● | ● | ● | ● |

| 80 | 117-140 | 4 5/8″-5 1/2″ | ● | ● | ● | ● |

| 88 | 130-152 | 5 1/8″-6″ | ● | ● | ● | ● |

| 96 | 141-165 | 5 9/16″-6 1/2″ | ● | ● | ● | ● |

| 104 | 157-178 | 6 3/16″-7″ | ● | ● | ● | ● |

| SAE Size No. | RANGE | SPECIFICATION | |

|---|---|---|---|

| Range mm | Range in | KG16Q | |

| – | 25-45 | 1"-1 3/4" | ● |

| 212 | 32-54 | 1 1/4"-2 1/8" | ● |

| 262 | 44-67 | 1 3/4"-2 5/8" | ● |

| 312 | 57-79 | 2 1/4"-3 1/8" | ● |

| 362 | 70-92 | 2 3/4"-3 5/8" | ● |

| 412 | 83-105 | 3 1/4"-4 1/8" | ● |

| 462 | 95-117 | 3 3/4"-4 5/8" | ● |

| 512 | 108-130 | 4 1/4"-5 1/8" | ● |

| 562 | 121-143 | 4 3/4"-5 5/8" | ● |

| 612 | 133-156 | 5 1/4"-6 1/8" | ● |

| 662 | 146-168 | 5 3/4"-6 5/8" | ● |

| 712 | 159-181 | 6 1/4"-7 1/8" | ● |

| 762 | 171-194 | 6 3/4"-7 5/8" | ● |

| 812 | 184-206 | 7 1/4"-8 1/8" | ● |

| 862 | 197-219 | 7 3/4"-8 5/8" | ● |

| 912 | 210-232 | 8 1/4"-9 1/8" | ● |

Difference Between Conventional & Heavy Duty Worm Clamp

Heavy-duty worm gear clamps offer stronger strength

Heavy-duty worm gear clamps differ from conventional clamps mainly in their reinforced construction. They feature thicker bands, wider widths, and upgraded screw housings that deliver significantly higher clamping force. This stronger structure helps maintain a stable, leak-free connection even under heavy vibration, pressure changes, or mechanical stress. As a result, HD worn clamps are more reliable for industrial, automotive, and high-pressure hose applications where standard clamps may loosen or deform over time.

Heavy-duty worm clamps with excellent corrosion resistance

Another major difference lies in corrosion performance. Heavy-duty clamps are made from higher-grade stainless steels such as 304 or 316, giving them exceptional resistance to rust, chemical exposure, moisture, and harsh outdoor environments. This improved material quality ensures long-term durability and reduces maintenance frequency. Whether used in marine systems, high-humidity areas, or demanding industrial setups, heavy-duty clamps offer far better protection and service life than conventional clamps.

Heavy duty worm gear clamp applications

01

in high-pressure construction environments

During early foundation work, the Heavy duty worm drive hose clamp provides strong holding power for supports and temporary structures. The firm grip of the HD Worm Drive Clamp helps prevent shifting or collapse, improving on-site safety.

02

in Heavy Industry

For heavy industrial equipment, the Heavy duty worm drive hose clamp offers reliable fastening on coolant lines, hydraulic hoses, and air systems. The firm tightening force of the HD worm gear clamp helps keep connections steady during continuous load and harsh operating conditions.

03

in Military

In military equipment, the HD worm gear clamp is commonly used to secure cooling hoses, air ducts, communication cables, and protective tubing. Its reinforced structure helps the Heavy duty worm drive clamp remain stable under shock, rapid movement, and demanding field conditions.

material grade of Heavy duty worm clamp

HWKG offers customizable heavy-duty worm clamps of various material grades, including W2, W3, W4, and W5. These are available to meet your diverse application needs.

W2 steel Heavy duty worm clamp

We provide W2 steel heavy duty worm gear clamp offers basic strength. Its corrosion resistance is moderate, making it suitable for indoor or low-moisture environments.

W3 steel Heavy duty worm clamp

At HWKG, our W3 steel, the HD worm drive clamp provides improved durability and slightly better corrosion protection, ideal for general industrial and outdoor use.

W4 steel Heavy duty worm clamp

We manufacture W4 steel HD worm gear clamp enhanced corrosion resistance, suitable for demanding conditions such as light chemical exposure or damp environments.

W5 steel Heavy duty worm clamp

With W5 steel, the Heavy duty worm gear clamp is designed for harsh, high-stress applications. Such as marine systems and coastal highly corrosive chemical industries.

steel series for Heavy duty worm gear clamp

200 series stainless steel

for heavy duty worm gear clamps

As a professional clamp manufacturer, HWKG offers heavy duty worm clamps made from 200 series stainless steel, delivering cost-effective corrosion resistance and dependable strength. This option is well-suited for general industrial use, indoor pipe connections, and environments with low to moderate moisture exposure.

300 series stainless steel

for heavy duty worm gear clamps

For projects requiring higher durability, HWKG supplies 300 series stainless steel HD worm drive hose clamps. With improved corrosion resistance, they perform reliably in outdoor installations, moisture-prone environments, and long-term hose or piping connections, offering steadier and more consistent fastening under regular use.

400 series stainless steel

for heavy duty worm gear clamps

To meet the needs of more demanding mechanical systems, HWKG produces 400 series stainless steel HD worm gear clamps, known for their increased mechanical strength and stable performance under torque. These clamps are commonly used in heavy machinery, high-stress assemblies, and equipment that requires secure, vibration-resistant fastening.

316 series stainless steel

for heavy duty worm gear clamps

For the toughest environments, HWKG provides 316 stainless steel heavy duty worm gear clamps, offering superior corrosion resistance and extended service life. This grade is ideal for harsh chemical processing, marine applications, and high-moisture or coastal environments where maximum reliability is essential.

Carbon steel VS stainless steel for heavy duty worm clamp screw

advantages of carbon steel screw fasteners

High tensile strength

Carbon steel screw fasteners are highly valued in heavy-duty worm clamp applications because of their exceptional tensile strength. This high tensile strength allows the fasteners to withstand substantial pulling forces without stretching, deforming, or failing under load. When installed in a heavy duty worm gear clamp, carbon steel screws help maintain a solid and reliable clamp tension, even when the hose or pipe system experiences pressure fluctuations or dynamic vibration. Their mechanical stability ensures the clamp remains securely tightened around thick-wall hoses commonly used in industrial, automotive, and mechanical environments. This level of strength is especially important for heavy-duty applications where safety and system integrity depend on the clamp’s ability to maintain consistent compression. Because carbon steel builds strong thread engagement, the screws provide dependable clamping force that performs well under high stress and repeated tightening cycles.

Excellent load-bearing capacity

The excellent load-bearing capacity of carbon steel screw fasteners makes them ideal for heavy duty worm drive clamps that operate in high-pressure or high-load systems. These screws can support significant mechanical stress, allowing the clamp to maintain its structural integrity when compressing thick hoses or reinforcing critical connections. Their ability to bear heavy loads ensures that the clamp remains stable even in demanding environments such as industrial machinery, hydraulic systems, and heavy transportation equipment. Carbon steel screws distribute force evenly through the band and housing of the clamp, minimizing slippage or loss of tension over time. This high load capacity also helps the clamp withstand sudden surges in pressure, shock loads, or mechanical impact without loosening. As a result, carbon steel fasteners deliver reliable performance that protects equipment from leaks, hose blowouts, and premature component failure.

Cost-effective option

A major advantage of carbon steel screw fasteners for heavy duty worm gear clamps is their cost-effectiveness. Compared to stainless steel, carbon steel offers strong mechanical performance at a more economical price, making it ideal for large-volume applications or general industrial systems where corrosion exposure is minimal. Despite their affordability, these screws still provide impressive durability, tensile strength, and torque resistance, giving users a high-value fastening solution. The lower cost of carbon steel fasteners makes them especially attractive for routine maintenance, equipment manufacturing, and large-scale installations where budget considerations are important. When used in heavy duty worm clamps, carbon steel screws deliver dependable tightening force without raising overall project costs. This balance of performance and affordability allows manufacturers and technicians to achieve reliable hose securing while keeping operational expenses under control.

Better torque transmission

Carbon steel screw fasteners provide better torque transmission due to their tough, rigid structure, which helps achieve a strong and consistent tightening effect on heavy-duty worm clamps. When torque is applied, carbon steel screws maintain thread stability and resist stripping, allowing the clamp to reach optimal compression without slipping. This is especially important for heavy-pressure hoses that require precise tightening to prevent leaks or movement. The superior torque transmission improves the clamp’s ability to deliver uniform sealing pressure along the band, enhancing performance under vibration, shock, and dynamic loads. Carbon steel’s mechanical reliability ensures that technicians can apply higher torque levels when needed, making them suitable for demanding industrial, automotive, and mechanical systems. Their ability to maintain torque over time also reduces the need for frequent re-tightening, contributing to long-term system stability.

advantages of stainless steel screw fasteners

Superior corrosion resistance

Stainless steel screw fasteners provide superior corrosion resistance, making them an ideal choice for heavy duty worm gear clamps used in harsh or moisture-rich environments. Stainless steel naturally resists rust, oxidation, and chemical exposure due to its high chromium content, ensuring long-lasting reliability even when exposed to water, salt, chemicals, or outdoor weather. This corrosion resistance allows the screws to maintain consistent tightening force without degrading or seizing. In applications such as marine equipment, wastewater systems, and outdoor industrial piping, stainless steel fasteners perform exceptionally well by preventing material breakdown that can compromise clamp performance. Their ability to maintain structural integrity helps ensure leak prevention and secure hose connections over long service cycles. This protective property also reduces the need for replacements and extends the lifespan of the entire clamp assembly, offering dependable performance in demanding conditions.

Long-lasting performance

Stainless steel screw fasteners are known for their long-lasting performance, making them highly suitable for heavy duty worm clamps that require durability over many years of operation. Their strong resistance to wear, fatigue, and environmental degradation ensures that they maintain tightening strength even after repeated torque cycles. Stainless steel also preserves its mechanical properties across a wide range of temperatures, making it stable in both high-heat and cold-weather applications. This long-term reliability is essential in industrial systems, marine environments, and high-vibration machinery where clamps must remain secure without frequent maintenance. The extended service life of stainless steel fasteners means equipment owners experience fewer failures, reduced downtime, and lower replacement costs. Overall, stainless steel screws contribute to a clamp system that performs consistently and safely across prolonged use.

Low maintenance

One of the key advantages of stainless steel screw fasteners is their low maintenance requirement. When used in heavy duty worm gear clamps, stainless steel screws retain their strength and appearance without the need for protective coatings or regular anti-rust treatments. Their inherent corrosion resistance means they do not degrade when exposed to water, chemicals, or outdoor humidity, significantly reducing the need for inspections and replacements. This is especially beneficial for systems that are difficult to access, such as underground pipelines, marine installations, and industrial equipment with minimal service intervals. Stainless steel’s stable performance ensures that the clamp continues to function reliably without loosening or seizing. As a result, technicians can trust the screws to maintain optimal clamping force while minimizing labor costs and downtime associated with frequent maintenance.

High aesthetic quality

Stainless steel screw fasteners also offer high aesthetic quality, which is an appealing advantage for clamps used in applications where visual appearance matters. Their clean, polished, and modern finish provides a professional look that enhances the overall appearance of the equipment. This makes stainless steel screws ideal for visible installations such as automotive engine bays, custom machinery, food-grade equipment, and architectural systems. Beyond appearance, the smooth surface finish also contributes to better corrosion resistance and easier cleaning. The material does not tarnish or discolor easily, ensuring long-term visual consistency even in environments exposed to moisture or chemicals. For manufacturers who value both function and presentation, stainless steel screws provide a premium visual impression while delivering reliable mechanical performance.

why choose HWKG as your Heavy duty worm clamp supplier

R&D Team for 30+ Years of Expertise

A team of over fifty experienced members

Our R&D department operates as a municipal-level technology center with a team of over 50 professional engineers. Among them is a technical consultant with more than 30 years of clamp-industry experience, and nearly half of the team members have over 10 years in the field. This experienced group uses digital platforms, modeling tools, and rapid verification methods to accelerate development and deliver customized clamp solutions with high efficiency.

Over 20 Years of HWKG Clamp Expertise

experts in providing clamp solutions

HWKG has accumulated more than 20 years of manufacturing experience in the design and production of hose clamps. Through continuous learning and refinement, the company has grown into a trusted manufacturer recognized for independent design, steady innovation, and reliable production capability. HWKG now supports well-known customers such as Rowes, Autozone, and HUAWEI, providing high quality clamp solutions.

free of defects such as porosity and cracks

Strict quality control of products

We applies a digital quality management system and advanced testing equipment to ensure precision and durability. Our inspection process covers every stage, from raw materials to final clamp application scenarios. Using instruments such as high-pressure testers and spark spectrographs, we verify performance and material integrity under real working conditions. With material options like 300 series stainless steel, we delivers clamps built for long-term and demanding environments.

FAQ

01 What is the strongest type of worm gear clamp?

The strongest type of worm gear clamp is the heavy duty worm gear clamp, which features a reinforced band, a high-torque screw mechanism, and a robust housing design. These clamps are engineered to handle higher pressure, stronger vibration, and more demanding industrial environments compared with standard worm gear clamps. Their construction typically uses thicker stainless steel bands and hardened screws to deliver maximum clamping force.

02 When to use Heavy duty worm gear clamps?

Heavy duty worm gear clamps should be used whenever the application requires higher pressure resistance, stronger vibration control, or a more secure hose connection.

Common situations include:

Industrial hoses and hydraulic systems

High-pressure air or fluid lines

Automotive turbo systems

Heavy machinery and construction equipment

Marine and outdoor environments

Compared with standard clamps, heavy-duty worm clamps maintain performance under extreme conditions and repeated stress.

03 What type of worn clamp is used in a pressurized area?

In pressurized systems, a heavy duty worm gear clamp is typically the preferred choice. Its reinforced band and high-strength screw provide a more stable sealing force under pressure. For extremely high-pressure or pulsating pressure applications, some users may also choose T-bolt clamps, but for most industrial and automotive pressurized hoses, HD worm gear clamps offer the best balance of strength, adjustability, and ease of installation.

04 What is the maximum pressure for a heavy duty worm gear clamp?

The maximum pressure a heavy duty worm gear clamp can handle depends on its band width, screw strength, and material grade, but in general, high-quality HD worm clamps can withstand 50–80 psi or more.

For reinforced stainless steel clamps or specialty industrial models, the pressure tolerance can be significantly higher. Always check manufacturer specifications, as performance varies based on clamp size and hose characteristics.

05 What is the difference between heavy duty worm clamp and T clamp?

The main differences between a heavy duty worm clamp and a T-clamp include:

difference in Design: Heavy duty worm gear clamps use a worm drive screw to tighten the band.

T-bolt clamps use a bolt and nut for linear compression.

06 How a Heavy duty worm gear clamp Works?

A heavy duty worm gear clamp works by using a worm-drive screw mechanism that engages with precision-cut slots on the clamp band. When the screw is turned:

The worm gear pulls the band tighter.Then the band contracts evenly around the hose.

A strong 360° sealing pressure is created between the hose and the fitting.

Because heavy duty worm clamps use thicker bands and stronger screws, they generate higher torque and better sealing performance, making them ideal for demanding, high-load applications.