china no hub coupling manufacturer

Compliant with the CUPC, ASTM C1277

A no hub coupling is a flexible pipe connector used to join cast iron, PVC, copper, or ABS pipes without the need for a hub or flange. It provides a secure and leak-resistant connection, making installation faster and easier in plumbing, drainage, and ventilation systems.

HWKG, a brand under Hengwei Hose Clamp Co., Ltd, is a professional no hub coupling manufacturer established in 2001 in Yuyao, Ningbo, Zhejiang, China. With over 20 years of experience and a 35,000-square-meter factory, HWKG has become one of the leading suppliers of hose clamps and pipe coupling products in China.

The following is HWKG’s detailed introduction to stainless steel no hub couplings and expert opinions on common questions.

Why choose to partner with HWKG

advanced manufacturing and innovation capability

strong r&d and technical expertise

certified quality and global recognition

hwkg no hub coupling technical specifications

- Patented Bi-Directional Shield Design

- Connects Cast lron Pipe to Cast lron Pipe

- Specially Beaded Gasket

- Interlocking Clamp Design

- Floating Eyelet Design

standard no hub pipe coupling specification table

| Part NO. | Size | Clamps Per Coupling | Install Torque |

| HW-NH150 | 1-1/2″ | 2 Pcs | 60 lbf·in |

| HW-NH22 | 2″ | ||

| HW-NH33 | 3″ | ||

| HW-NH44 | 4″ | ||

| HW-NH55 | 5″ | 4 Pcs | |

| HW-NH66 | 6″ | ||

| HW-NH88 | 8″ | ||

| HW-NH1010 | 10″ |

medium duty no hub pipe coupling specification table

| Part NO. | Size | Clamps Per Coupling | Install Torque |

| HW-MD150 | 1-1/2″ | 4 Pcs | 80 lbf·in |

| HW-MD22 | 2″ | ||

| HW-MD33 | 3″ | ||

| HW-MD44 | 4″ | ||

| HW-MD55 | 5″ | 6 Pcs | |

| HW-MD66 | 6″ | ||

| HW-MD88 | 8″ | ||

| HW-MD1010 | 10″ |

heavy duty no hub coupling specification table

| Part NO. | Size | Clamps Per Coupling | Install Torque |

| HW-HD22 | 2″ | 4 Pcs | 80 lbf·in |

| HW-HD33 | 3″ | ||

| HW-HD44 | 4″ | ||

| HW-HD55 | 5″ | 6 Pcs | |

| HW-HD66 | 6″ | ||

| HW-HD88 | 8″ | ||

| HW-HD1010 | 10″ |

reducing size no hub coupling specification table

| Part NO. | Size | Clamps Per Coupling | Install Torque |

| HW-NH215 | 2″×1-1/2″ | 4 Pcs | 60 lbf·in |

| HW-NH32 | 3″×2″ | ||

| HW-NH42 | 4″×2″ | ||

| HW-NH43 | 4″×3″ |

key advantages of no hub connector

superior watertight sealing performance

Engineered stainless-steel bands and rubber gaskets create a secure watertight seal, ensuring reliable connections and long-term moisture resistance.

effective leakage prevention design

A reinforced metal shield and elastic sleeve maintain tight pipe joints, preventing vibration, displacement, and unwanted fluid leaks efficiently.

excellent pressure and load resistance

The reinforced stainless steel housing and durable rubber materials maintain performance even in demanding industrial conditions.

noise and vibration reduction capability

The flexible rubber layer absorbs vibration and reduces noise during fluid flow, providing a quieter, more comfortable pipe system.

easy and quick installation process

Lightweight design and simple tightening structure allow fast installation without welding, adhesives, or special tools, saving time.

compatibility with multiple pipe materials

No hub couplings connect PVC, cast iron, copper, and ABS pipes seamlessly, providing versatility and convenience for various plumbing systems.

What are the three types of no hub pipe coupling

standard no hub pipe coupling

Standard no hub pipe couplings are designed for everyday plumbing needs, offering reliable sealing, flexibility, and corrosion resistance. They are typically used to connect residential drainage pipes, bathroom or kitchen sinks, and low-pressure water systems operating at approximately 0.9 PSI (6.2 KPA). Their lightweight design allows quick installation and easy maintenance, making them ideal for home renovation projects or small-scale plumbing repairs.

medium duty no hub pipe coupling

Medium duty no hub pipe couplings provide enhanced strength and durability compared to standard types. Designed to handle up to about 2.2 PSI (15.1 KPA), they can withstand moderate pressure and vibrations, making them suitable for commercial plumbing, HVAC systems, and mid-sized industrial water supply networks. These couplings also accommodate slight misalignments between pipes, ensuring consistent sealing performance and improved system longevity.

heavy duty no hub coupling

Heavy duty no hub couplings are built for high-pressure and high-stress environments. Based on the original design, the width was increased and multiple clamps were added in the middle to make the force distribution more even, the strength higher, and the connection more stable. HWKG’s heavy duty model has a maximum test pressure of 4.3 PSI (29.6 KPA). They are ideal for municipal pipelines, industrial drainage systems, and large-scale mechanical installations. Couplings conform to CISPI 310, Factory Mutual EN 1680. Couplings comply with ASTM C564, ASTM C1540, IAPMOfile #3198, Gaskets are made from anelastomeric compound that meets the requirements of ASTM C564.

hubless coupling in different applications

HWKG offers 1″–10″ hubless couplings that feature patented bi-directional shielding technology, which maximizes the transfer of pressure from the clamp to the gasket and pipe. This design provides a more efficient and reliable connection, effectively replacing traditional, less efficient hub-and-spigot joints. The following sections highlight the specific applications of no hub pipe couplings in various piping scenarios.

pvc to cast iron no hub coupling

When connecting PVC to cast iron, the main concern is differential expansion and material rigidity, which can cause leaks or stress on the joint. HWKG’s PVC to cast iron no hub couplings use a flexible rubber sleeve and evenly tightened stainless steel clamp to absorb movement and maintain a tight, watertight seal.

cast iron to abs no hub adapter

Connecting cast iron to ABS requires vibration resistance and pressure distribution because ABS is lighter and more flexible than cast iron. HWKG’s cast iron to abs no hub adapters feature a reinforced metal shield and bi-directional clamp design, ensuring consistent pressure transfer to the gasket and reducing the risk of displacement or leaks.

cast iron to cast iron no hub coupling

For cast iron to cast iron connections, the challenge is high pressure and mechanical load. HWKG heavy duty no hub couplings use thick rubber sleeves combined with strong stainless steel bands to provide maximum compression and maintain durability under heavy loads, suitable for municipal or industrial drainage systems.

no hub coupling pvc to copper

When joining PVC and copper, thermal expansion and material stiffness differences can stress the joint. HWKG no hub coupling pvc to copper uses a flexible rubber sleeve that absorbs expansion and a bi-directional clamp that distributes pressure evenly, ensuring leak-free, stable connections for water supply and HVAC applications.

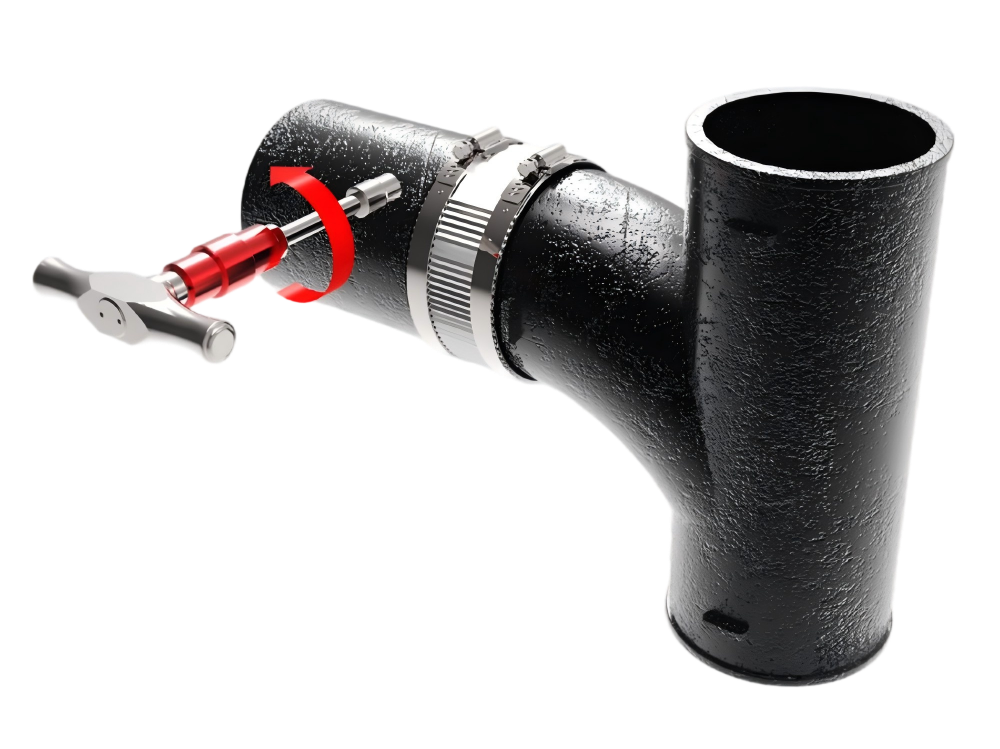

How do you install a hubless pipe coupling

Prepare the pipe ends

Clean and smooth both pipe ends by removing rust, burrs, and debris. Ensure the surfaces are dry and properly aligned before installation.

Position the rubber sleeve

Slide the rubber sleeve onto one pipe end, then align the second pipe so both ends meet evenly inside the sleeve without gaps.

Install the metal shield and clamps

Place the stainless steel shield over the sleeve, ensuring it is centered on the joint. Position all clamps correctly before tightening.

Tighten and test the connection

Evenly tighten all clamps with a torque wrench according to specifications. Inspect the joint and perform a pressure or water test to confirm a secure seal.

FAQ about no hub couplings

Are no hub bands allowed underground?

Yes, no hub bands are allowed underground, but only if they are specifically rated and approved for underground use. Standard no hub couplings are typically designed for above-ground or indoor applications, such as connecting pipes in drainage or vent systems.

For underground installations, it’s important to use shielded no hub coupling or heavy-duty no hub couplings that feature corrosion-resistant stainless steel shields and robust rubber sleeves. These components prevent soil moisture, pressure, and temperature changes from compromising the seal.

Always check local plumbing codes and product certifications (such as CUPC or ASTM C1277) to ensure the selected coupling meets underground installation standards. Using the proper type guarantees durability, leak resistance, and long-term performance beneath the surface.

Can you weld no hub couplings?

No, you cannot weld no hub couplings. These couplings are specifically designed for mechanical connections, not welded joints. They use stainless steel clamps and flexible rubber sleeves to create a secure, watertight seal between pipes without heat or fusion.

Welding would damage the rubber sleeve and compromise the stainless steel shield, leading to leaks or joint failure. The strength of a no hub coupling comes from uniform mechanical compression, not from a welded bond.

If a permanent, welded joint is required, you should use metal pipes and compatible welding fittings instead. For most drainage, vent, and non-pressurized systems, no hub pipe couplings provide a safer, faster, and easier alternative to welding.