China non perforated hose clamps manufacturer

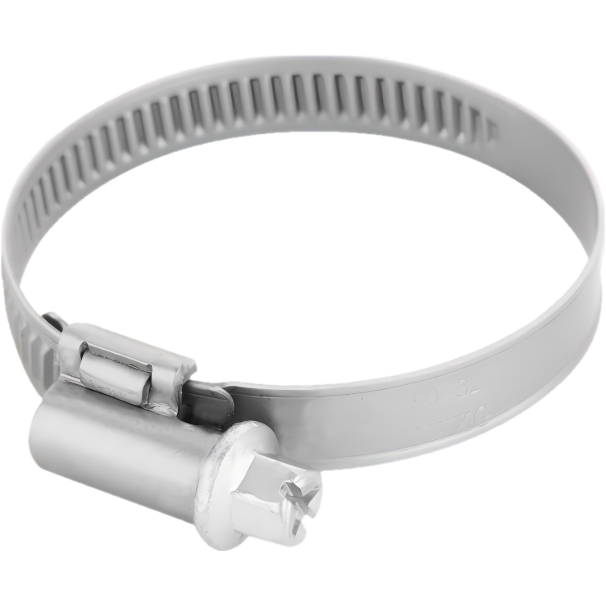

Non perforated hose clamps are also known as embossed hose clamps. The term “embossed” refers to the raised pattern on the clamp band that enhances grip and strength while maintaining a smooth inner surface. This design helps protect silicone and other soft hose from scratches or cuts, making it ideal for delicate or soft hoses.

A reliable supplier ensures consistent quality, accurate dimensions, corrosion resistance, and long service life. Choose HWKG for durable, precision-engineered embossed hose clamps trusted by global industries for quality, reliability, and performance.

why choose HWKG as your non perforated hose clamps supplier?

HWKG is your reliable partner for non perforated hose clamps, we deliver dependable solutions for customers worldwide. When you choose HWKG, you can expect:

Comprehensive product range

We provide a complete selection of hose clamps, bolt clamps, band clamps and pipe couplings. Our products meet diverse industrial needs with precise design, stable performance, and reliable sealing for automotive, machinery, and communication applications.

Trusted by global partners

HWKG collaborates with world-renowned companies such as Rowes, AutoZone, and Huawei. Our dedication to quality, integrity, and innovation has earned us lasting trust and partnerships across Europe, America, and Asia.

OEM and ODM customization support

We offer flexible OEM and ODM services to create customized clamp solutions. Our professional design and mold teams develop products according to specific requirements, ensuring high precision, consistent quality, and timely delivery for global customers.

basic structure of non perforated band hose clamp

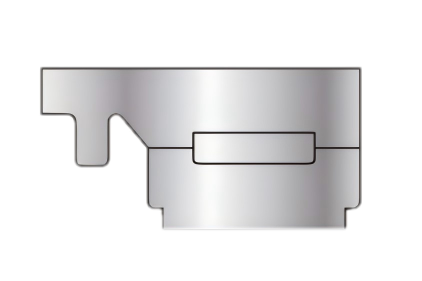

screw

External hexagon screw, multiple materials, head sizes, and screw slot types are available for selection

housing

Asymmetrical design of the housing

band

Edge-crimped steel band with non-perforated tooth structure, which does not damage the hose during installation

DP09B

Band

Stainless Steel

Housing

Stainless Steel

Hex Head

Carbon Steel Or 400 Series Stainless Steel

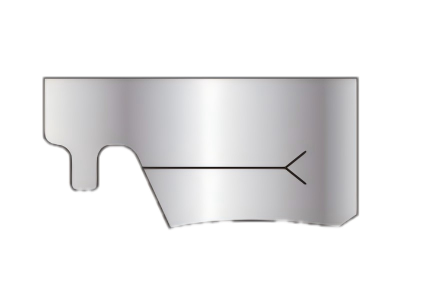

DP12B

Band

Stainless Steel

Housing

Stainless Steel

Hex Head

Carbon Steel Or 400 Series Stainless Steel

HWKG provides following non perforated band hose clamp

non perforated band hose clamp Parameters

non perforated band hose clamp configuration table

| SPECIFICATION | MATERIAL | BAND | HOUSING | SCREW |

| DP09B / DP12.5B / DP12B | W2 | 200/300 series stainless steel | 200/300 series stainless steel | carbon steel |

| W3 | 400 series stainless steel | 400 series stainless steel | 400 series stainless steel | |

| DP09Q / DP12.5Q / DP12Q | W4 | 300 series stainless steel | 300 series stainless steel | 300 series stainless steel |

| Customization of specifications and material configurations is available based on customer requirements. The above information is for reference only and should not be considered as technical specifications. | ||||

non perforated band hose clamp specification table

| RANGE | SPECIFICATION | |||||

| RANGE mm | DP09B | DP09Q | DP12.5B | DP12.5Q | DP12B | DP12Q |

| 8-12 | • | • | ||||

| 10-16 | • | • | ||||

| 12-22 | • | • | ||||

| 16-27 | • | • | ||||

| 20-32 | • | • | • | • | ||

| 25-40 | • | • | • | • | ||

| 35-50 | • | • | • | • | • | • |

| 40-60 | • | • | • | • | • | • |

| 50-70 | • | • | • | • | • | • |

| 60-80 | • | • | • | • | • | • |

| 70-90 | • | • | • | • | • | • |

| 80-100 | • | • | • | • | • | • |

| 90-110 | • | • | • | • | • | • |

| 100-120 | • | • | • | • | • | • |

| 110-130 | • | • | • | • | • | • |

| 120-140 | • | • | • | • | • | • |

| 130-150 | • | • | • | • | • | • |

| 140-160 | • | • | • | • | • | • |

perforated vs non perforated hose clamps

Hose clamps are essential components in many industries, and non perforated hose clamps play a crucial role in protecting hoses and ensuring secure connections. Next, we will provide a detailed comparison of non perforated and perforated hose clamps, helping customers make informed choices with professional guidance.

when to use non perforated hose clamps

Non perforated hose clamps feature a smooth inner band with embossed patterns and reinforced edges to optimize pressure distribution and prevent hose damage. The structural enhancements ensure a stable seal and minimize slippage. They are widely used in automotive cooling and fuel systems, hydraulic machinery, HVAC pipelines, and industrial fluid transfer applications.

when to use perforated hose clamps

Perforated hose clamps feature slots or holes along the band for flexible adjustment and easy installation. They are ideal for cost-effective, general-purpose applications such as plumbing, low-pressure connections, and hardware tools.

key advantages of non perforated band hose clamp

prevents hose damage effectively

non perforated band hose clamp has a smooth inner surface with embossed patterns that protect the hose from scratches, cuts, or deformation. This design ensures long-term hose integrity, especially for soft or delicate materials in automotive and industrial applications.

fits in restricted or tight spaces

The slim and smooth design of non perforated hose clamps allows installation in confined areas where perforated clamps may not fit. They are ideal for compact engine compartments, tight machinery layouts, and other space-limited environments.

provides a stable and even seal

Embossed patterns on the clamp band distribute pressure evenly around the hose, creating a reliable and leak-free seal. This feature is critical in high-pressure systems such as hydraulic machinery, fuel lines, and HVAC pipelines.

maintains long-term connection

Non perforated band hose clamp firmly secures hoses to prevent slippage or loosening over time. Their robust construction ensures stable connections in automotive, industrial, and engineering machinery applications.

suitable for various applications

These non perforated hose clamps are used across various industries, including automotive, plumbing, and communication equipment. Their versatility and protective design make them ideal for both standard and high-demand environments.

embossed hose clamps in different applications

cooling system hoses in engines

Embossed hose clamps secure radiator and coolant hoses in engines, preventing leaks under high temperature and pressure. Their smooth inner surface protects hoses from cracking, ensuring stable fluid circulation and avoiding engine overheating or system failure.

fuel and oil lines

These clamps provide consistent pressure on fuel and oil transfer hoses, creating a tight seal. They prevent leakage, reduce safety hazards, maintain stable system performance, and ensure smooth operation of high-pressure pipelines in vehicles or machinery.

hydraulic machinery connections

Embossed hose clamps hold hydraulic hoses in equipment such as cranes, excavators, and injection molding machines. They prevent slippage, maintain pressure integrity, reduce downtime from leaks, and ensure long-term reliable performance in demanding conditions.

HVAC and refrigeration systems

In air conditioning and refrigeration units, embossed hose clamps secure refrigerant hoses tightly. They prevent leaks, reduce vibration-related wear, maintain efficient cooling performance, and protect hoses from long-term damage in complex system layouts.

plumbing and water supply pipelines

Embossed hose clamps are applied to flexible water supply and drainage hoses, preventing detachment under pressure. They reduce leaks, protect hoses from abrasion, maintain consistent flow, and ensure reliable operation in residential or industrial plumbing systems.

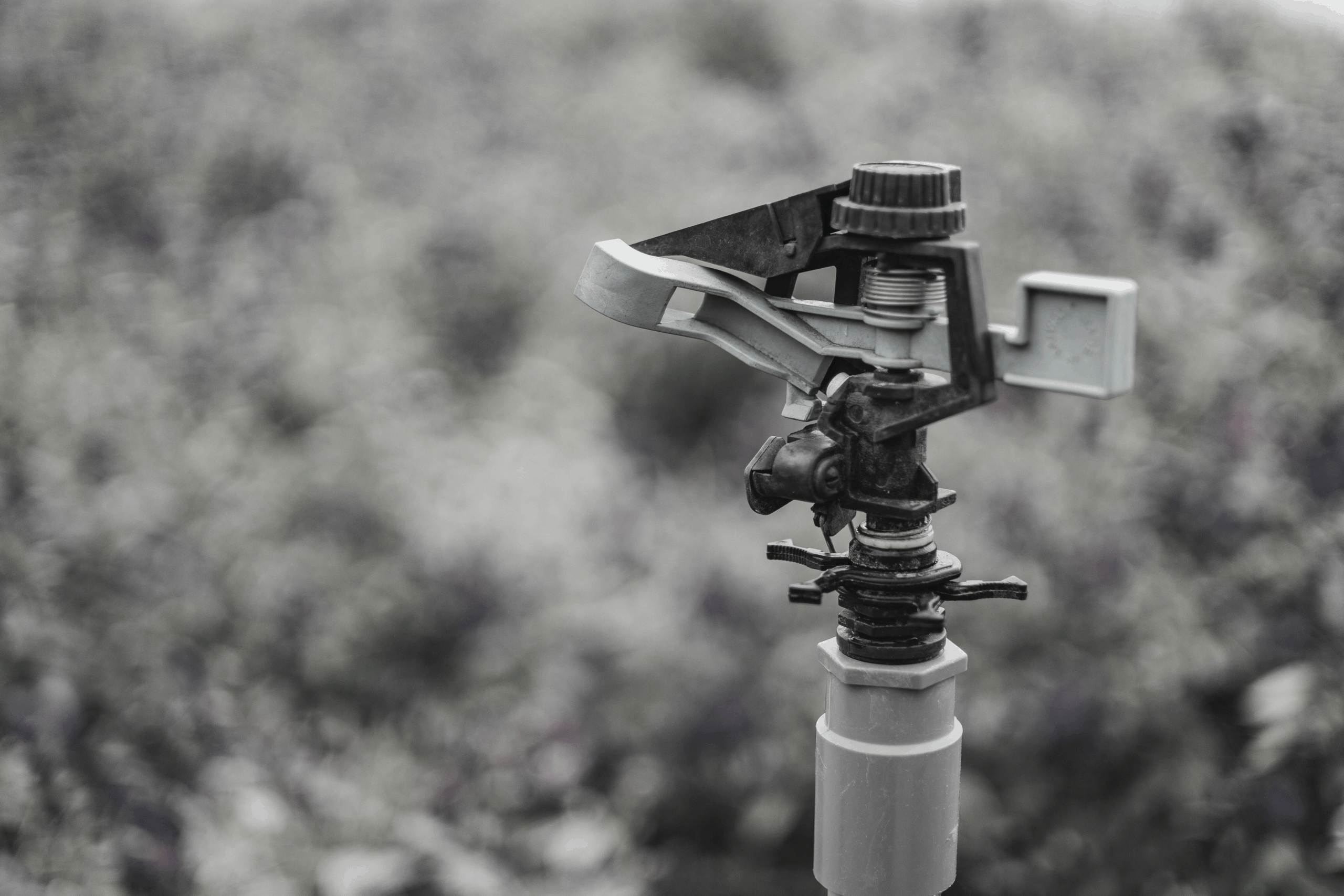

agricultural irrigation equipment

In irrigation systems, embossed hose clamps fasten flexible hoses connecting water pumps, sprinklers, and filters. They provide a tight, durable seal, prevent leaks during high-flow operation, and maintain stable water pressure for efficient and consistent crop irrigation.

embossed worm gear hose clamp faq

how to choose embossed worm gear hose clamp

As an expert from HWKG, I always emphasize that choosing the right embossed worm gear hose clamp is essential for achieving a secure seal, long service life, and reliable performance in different working environments. Based on our years of production and testing experience, here are the key factors I recommend considering:

1. Confirm hose size compatibility and band proportion

We always begin by checking the hose size after it is installed on the fitting. The clamp should offer sufficient adjustment range to ensure a snug and stable fit without over-tightening. Selecting an appropriate band width is also important, as it helps distribute clamping force evenly and improves overall stability for different hose types and applications.

2. Evaluate material selection and corrosion resistance

Material choice plays a critical role in long-term performance. Stainless steel options are widely used for their durability and corrosion resistance in most general applications. For harsher environments such as marine, chemical, or outdoor use, higher-grade stainless steel provides better resistance. I generally advise against surface-coated clamps when long-term exposure to moisture or corrosive conditions is expected.

3. Assess the embossed band design

A properly designed embossed band improves grip while protecting the hose surface. Non-perforated designs are especially effective, as they deliver strong holding force without cutting into soft hose materials like rubber or silicone. This balance is essential for maintaining sealing integrity over time.

4. Match clamp strength to application demands

Different systems require different levels of clamping strength. Light-duty applications can be handled with standard clamps, while more demanding systems benefit from reinforced designs that offer higher stability and resistance to deformation. Choosing the right clamp strength helps prevent leakage and extends service life.

5. Verify quality control and certification standards

Finally, I always recommend checking manufacturing standards and certifications. At HWKG, all hose clamps are produced under internationally recognized quality management systems. This ensures consistent materials, reliable workmanship, and dependable performance across a wide range of applications.

embossed worm gear clamps alternatives

Understanding embossed worm gear clamps

Embossed worm gear clamps feature a smooth inner surface with embossed reinforcement, preventing hose damage while ensuring a strong, uniform seal. They are ideal for delicate materials such as silicone or rubber hoses used in high-vibration or high-temperature environments.

spring hose clamp

Spring hose clamps automatically adjust to temperature and pressure changes, maintaining consistent sealing even during expansion or contraction. They are widely used in cooling systems, engines, and thermal cycling environments where constant tension is required for safety.

ear clamp

Ear clamps use a one-time crimping mechanism to secure hoses tightly and evenly. They provide a compact, space-saving design and are ideal for small-diameter hoses in fuel lines, air systems, and other applications requiring permanent, tamper-proof connections.

constant tension hose clamp

These clamps use a self-adjusting spring mechanism that maintains pressure under fluctuating temperatures or vibrations. They are ideal for marine, chemical, and heavy industrial systems, providing long-term corrosion resistance and stable performance in extreme conditions.

how do you install a stainless steel embossed clamp

Installing a stainless steel embossed hose clamp correctly is essential for ensuring a secure, leak-free, and long-lasting connection. Below is a detailed guide on how to properly install a stainless steel embossed clamp. If you encounter any problems during installation, please feel free to contact our experts.

Step 1: Prepare the hose and fitting

Clean both the hose and fitting thoroughly to remove oil, dirt, or debris that could affect the seal. Cut the hose end cleanly using a sharp cutter to ensure a smooth edge for proper fitment and strong sealing performance.

Step 2: Position and align the clamp

Slide stainless steel embossed clamp onto the hose before attaching the hose to the fitting. Once positioned, move it directly over the connection point and make sure the band lies flat and even around the hose. Keep the screw housing easily accessible to ensure smooth and accurate tightening.

Step 3: Tighten and inspect the connection

Using a screwdriver or torque wrench, tighten stainless steel embossed clamp slowly until it fits snugly. Avoid over-tightening to prevent hose deformation. After tightening, inspect the clamp to confirm even compression and test for leaks or slippage during initial operation.

Step 4: Maintain and recheck regularly

After initial use, recheck the clamp to ensure stability, especially in systems exposed to vibration or heat. If necessary, gently re-tighten. Regular inspection helps maintain consistent sealing and prolong the lifespan of both the clamp and the hose.