china spring loaded t bolt clamp manufacturer

Compliant with the SAEJ1508 standard,Type “SLTB”

This type of clamp belongs to bolted structure clamp. Adopting a spring structure, provides continuous torque compensation under temperature variation. It has a higher torque and adapt to more environments.

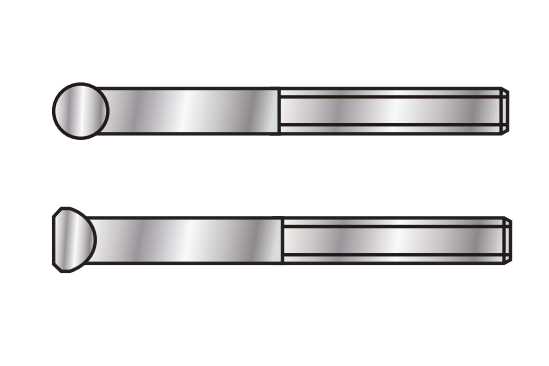

basic structure of spring loaded t bolt clamp

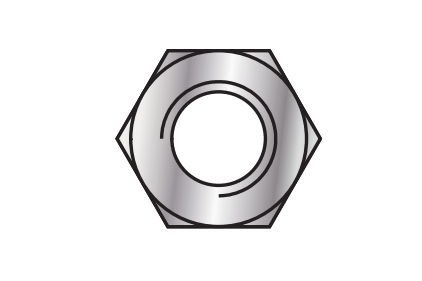

7/16" hex nut nylon insert

Material options include carbon steel with various plating treatments available.Corresponding self-locking nuts can be selected based on different temperature scenarios

spring

Spring steel can withstand and provide continuous torque compensation

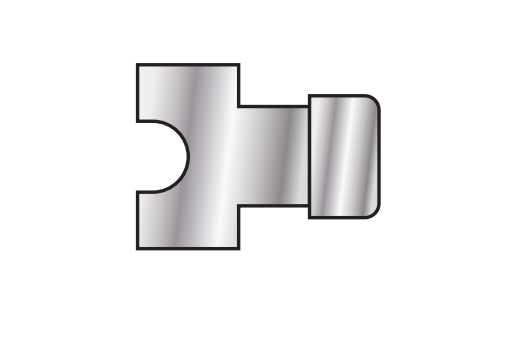

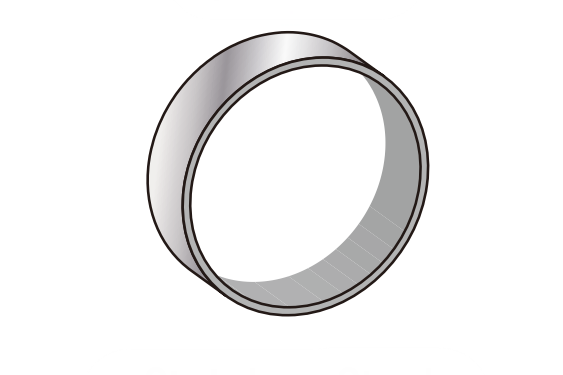

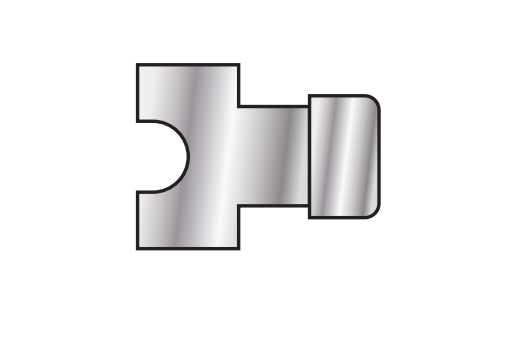

trunnion

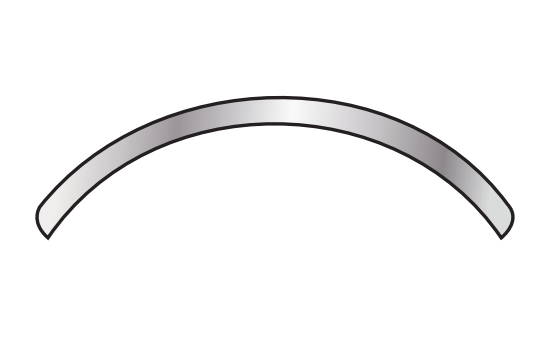

bridge

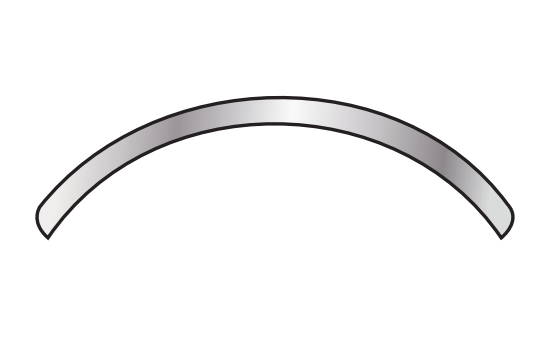

300 series stainless steel and variety of structures are available with a curevd design for perfect fit

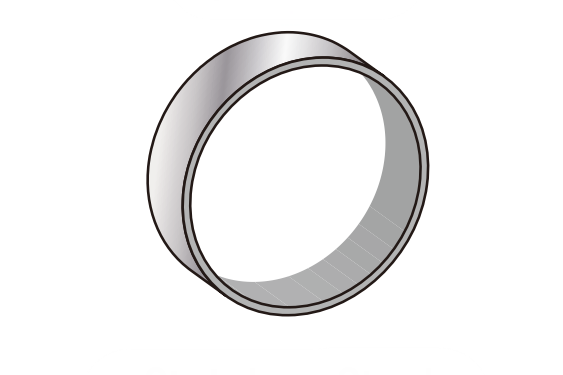

band

One-piece steel stripwith dependable strength

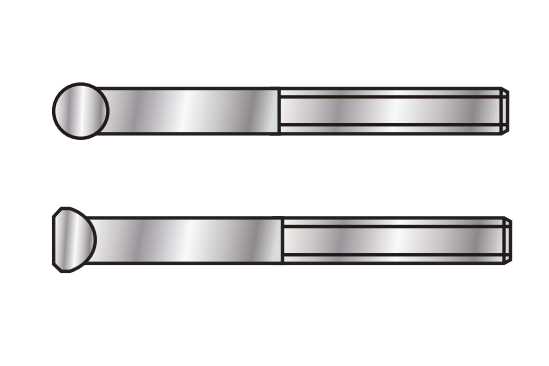

t-bolt

Various material choices available, with surface treatments available such as passivation and plating. Bolt’s corresponding strength and thread type can be selected based on different load requirements

gasket

Carbon steel, plating treatment available

heavy-duty compression spring

Providing higher load capadty and sustained torque compensation

hexagon flange nut

Uniform force distri botion in the limit spring

TX19BC1

Band

Stainless Steel

Bridge

Stainless Steel

Trunnion

Stainless Steel

T-bolt

Stainless Steel

Hex Nut Nylon Insert

Stainless Steel

Spring

Spring Steel

TX19BC2

Band

Stainless Steel

Bridge

Stainless Steel

Trunnion

Stainless Steel

T-bolt

Carbon Steel

Gasket

Carbon Steel

Heavy-duty Compression Spring

Spring Steel

Gasket

Carbon Steel

Hexagon Flange Nut

Carbon Steel

spring loaded t bolt clamp Parameters

spring loaded t bolt clamps configuration table

| SPECIFICATION | MATERIAL | BAND | BRIDGE | TRUNNION | 1/4″ T-BOLT | 7/16″ HEX NUT NYLON INSERT | SPRING | GASKET |

| TX19BC1 | W2 | 300 series stainless steel | 300 series stainless steel | 300 series stainless steel | carbon steel | carbon steel | Spring steel | — |

| TX19BC2 | W2 | 300 series stainless steel | 300 series stainless steel | 300 series stainless steel | carbon steel | carbon steel | Spring steel | carbon steel |

| Customizaton of specifications and material configurations is available based on customer requirements. The above information is for reference only and should not be considered as technical specifications | ||||||||

spring loaded t bolt clamps specification table

| SAE Size No. | RANGE | SPECIFICATION | ||

| RANGE mm | RANGE IN | SPECIFICATION TX19BC1 | SPECIFICATION TX19BC2 | |

| 34 | 50-58 | 1 15/16″-2 1/4″ | • | • |

| 40 | 54-62 | 2 1/8″-2 7/16″ | • | • |

| 46 | 59-67 | 2 5/16″-2 5/8″ | • | • |

| 52 | 64-72 | 2 1/2″-2 13/16″ | • | • |

| 58 | 69-77 | 2 11/16″-3″ | • | • |

| 64 | 73-81 | 2 7/8″-3 3/16″ | • | • |

| 70 | 78-86 | 3 1/16″-3 3/8″ | • | • |

| 76 | 83-91 | 3 1/4″-3 9/16″ | • | • |

| 82 | 88-96 | 3 7/16″-3 3/4″ | • | • |

| 88 | 92-100 | 3 5/8″-3 15/16″ | • | • |

| 94 | 97-105 | 3 13/16″-4 1/8″ | • | • |

| 100 | 102-110 | 4″-4 5/16″ | • | • |

| 108 | 108-116 | 4 1/4″-4 9/16″ | • | • |

| 116 | 114-122 | 4 1/2″-4 13/16″ | • | • |

| 124 | 121-129 | 4 3/4″-5 1/16″ | • | • |

| 132 | 127-135 | 5″-5 5/16″ | • | • |

| 140 | 134-142 | 5 1/4″-5 9/16″ | • | • |

| 148 | 140-148 | 5 1/2″-5 13/16″ | • | • |

| 156 | 146-154 | 5 3/4″-6 1/16″ | • | • |

| 164 | 153-161 | 6″-6 5/16″ | • | • |

| 172 | 159-167 | 6 1/4″-6 9/16″ | • | • |

| SAE Size No. | RANGE | SPECIFICATION | ||

| RANGE mm | RANGE IN | SPECIFICATION TX19BC1 | SPECIFICATION TX19BC2 | |

| 180 | 165-173 | 6 1/2″-6 13/16″ | • | • |

| 188 | 172-180 | 6 3/4″-7 1/16″ | • | • |

| 196 | 178-186 | 7″-7 5/16″ | • | • |

| 204 | 184-192 | 7 1/4″-7 9/16″ | • | • |

| 212 | 191-199 | 7 1/2″-7 13/16″ | • | • |

| 220 | 197-205 | 7 3/4″-8 1/16″ | • | • |

| 228 | 204-212 | 8″-8 5/16″ | • | • |

| 236 | 210-218 | 8 1/4″-8 9/16″ | • | • |

| 244 | 216-224 | 8 1/2″-8 13/16″ | • | • |

| 252 | 223-231 | 8 3/4″-9 1/16″ | • | • |

| 260 | 229-237 | 9″-9 5/16″ | • | • |

| 268 | 235-243 | 9 1/4″-9 9/16″ | • | • |

| 276 | 242-250 | 9 1/2″-9 13/16″ | • | • |

| 284 | 248-256 | 9 3/4″-10 1/16″ | • | • |

| 292 | 254-262 | 10″-10 5/16″ | • | • |

| 300 | 261-269 | 10 1/4″-10 9/16″ | • | • |

| 308 | 267-275 | 10 1/2″-10 13/16″ | • | • |

| 316 | 273-281 | 10 3/4″-11 1/16″ | • | • |

| 324 | 280-288 | 11″-11 5/16″ | • | • |

| 332 | 286-294 | 11 1/4″-11 9/16″ | • | • |

| 340 | 292-300 | 11 1/2″-11 13/16″ | • | • |