t-bolt hose clamp manufacturer and supplier

Compliant with the SAE J1508

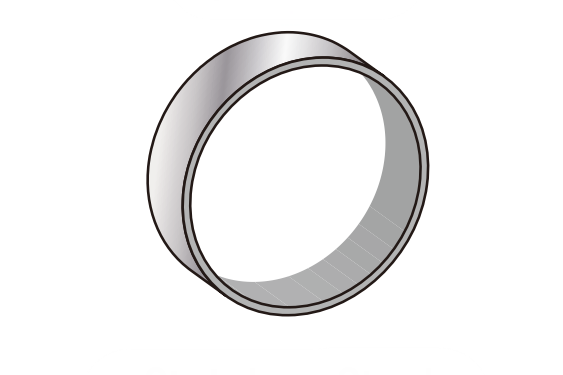

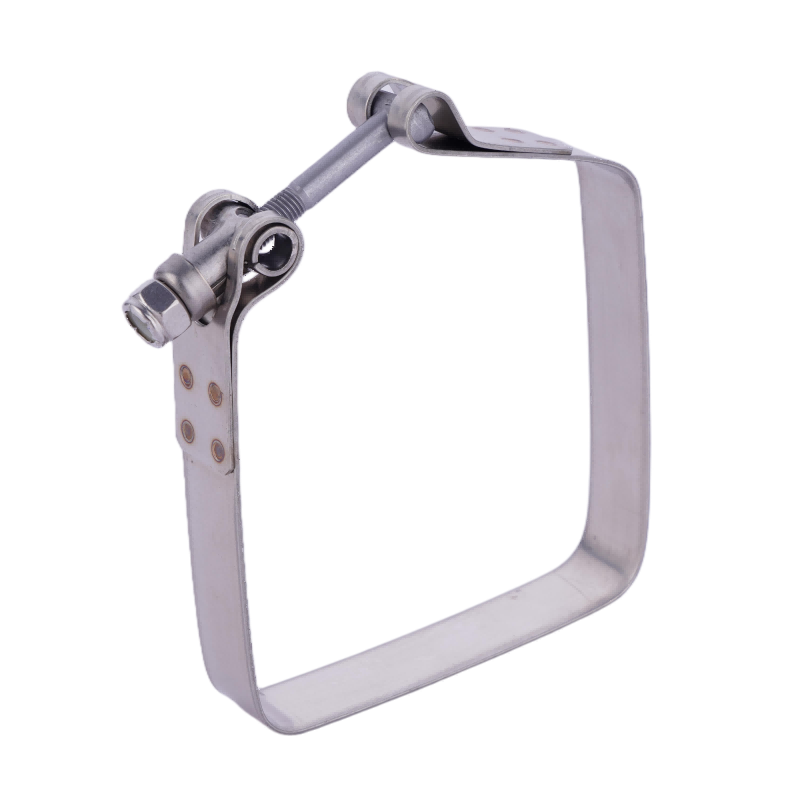

A T-bolt clamp is a high-strength bolted clamp constructed from a durable stainless-steel band paired with a forged T-bolt and a self-locking nut, delivering uniform tightening and reliable sealing across the clamped surface. Its robust, one-piece fastening design resists loosening from vibration and maintains consistent compression under high pressure or thermal cycling.

We provide a wide range of sizes along with customizable options to meet different hose and pipe requirements. Each clamp is manufactured from advanced production technology, ensuring exceptional durability and reliable strength under demanding conditions.

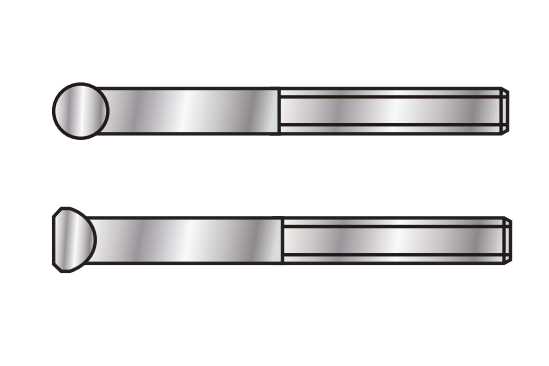

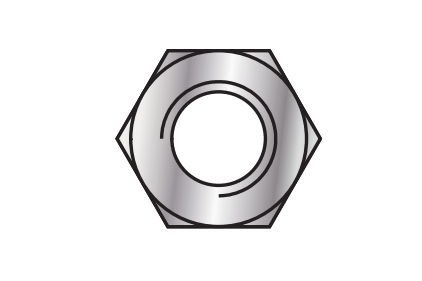

Basic structure of t-bolt clamp

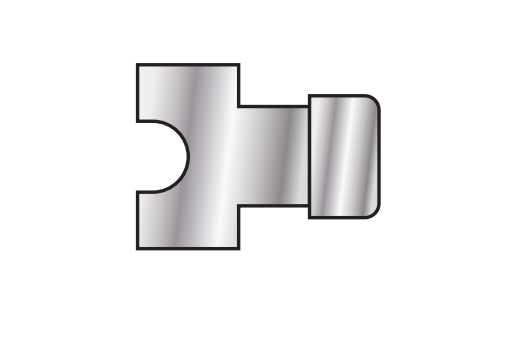

Trunnion

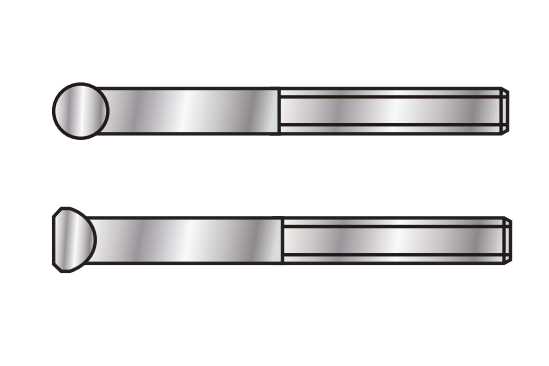

Hex nut nylon insert

Different self-locking nuts with specific functions can be selected based on different temperature scenarios.

Band

One-piece steel strip with dependable strength.

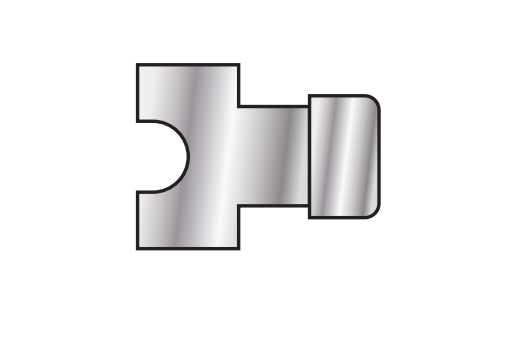

T-bolt

Various material choices availah (should be “available”), with surface treatments available such as passivation and plating. Bolt’s corresponding strength and thread type can be selected based on different load requirements.

Surface options

Zinc plating: Aesthetically pleasing appearance; accessories can withstand neutral salt spray tests for 24/48/72 hours without red rust.

Dacromet plating: Accessories can withstand neutral salt spray tests for 120-500 hours without red rust.

self-locking structure

Nylon self-locking structure can withstand temperatures up to 250℃.

All-metal self-locking structure can withstand temperatures up to 500℃.

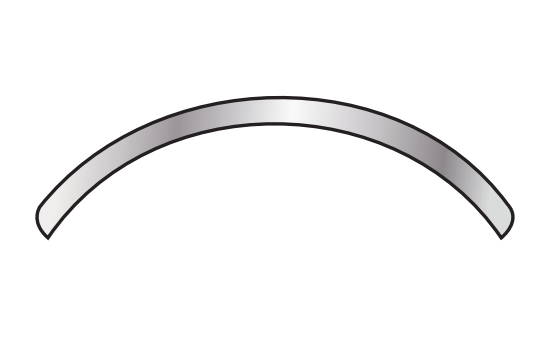

Bridge

Seamless sealing structure and variety of structures are available with a curved design for perfect fit.

HWKG models of T-bolt hose clamp

TX19Q

Band

Stainless Steel

Bridge

Stainless Steel

Trunnion

Stainless Steel

T-bolt

Stainless Steel

Hex Nut Nylon Insert

Stainless Steel

TX19B

Band

Stainless Steel

Bridge

Stainless Steel

Trunnion

Stainless Steel

T-bolt

Carbon Steel

Hex Nut Nylon Insert

Carbon Steel

HWKG T-Bolt Hose Clamp Configuration Table

| SPECIFICATION | MATERIAL | BAND | BRIDGE | TRUNNION | 1/4″ T-BOLT | 7/16″ HEX NUT NYLON INSERT |

|---|---|---|---|---|---|---|

| TX19B | W2 | 200/300 series stainless steel | 200/300 series stainless steel | 200/300 series stainless steel | carbon steel | carbon steel |

| TX19Q | W4 | 200/300 series stainless steel | 200/300 series stainless steel | 200/300 series stainless steel | 200/300 series stainless steel | 200/300 series stainless steel |

| W5 | 316 stainless steel | 316 stainless steel | 316 stainless steel | 316 stainless steel | 316 stainless steel | |

| Customization of specifications and material configurations is available based on customer requirements. The above information is for reference only and should not be considered as technical specifications. | ||||||

HWKG T-Bolt Hose Clamp Specification Table

| SAE Size No. | RANGE | SPECIFICATION | ||

|---|---|---|---|---|

| RANGE mm | RANGE IN | TX19B | TX19Q | |

| – | 32–37 | 1 1/4″–1 7/16″ | ● | ● |

| – | 35–40 | 1 3/8″–1 9/16″ | ● | ● |

| – | 38–43 | 1 1/2″–1 11/16″ | ● | ● |

| – | 41–46 | 1 5/8″–1 7/8″ | ● | ● |

| 28 | 44–52 | 1 3/4″–2″ | ● | ● |

| 30 | 46–54 | 1 13/16″–2 1/16″ | ● | ● |

| 34 | 50–58 | 1 15/16″–2 1/4″ | ● | ● |

| 40 | 54–62 | 2 1/8″–2 7/16″ | ● | ● |

| 46 | 59–67 | 2 5/16″–2 5/8″ | ● | ● |

| 52 | 64–72 | 2 1/2″–2 13/16″ | ● | ● |

| 58 | 69–77 | 2 11/16″–3″ | ● | ● |

| 64 | 73–81 | 2 7/8″–3 3/16″ | ● | ● |

| 70 | 78–86 | 3 1/16″–3 3/8″ | ● | ● |

| 76 | 83–91 | 3 1/4″–3 9/16″ | ● | ● |

| 82 | 88–96 | 3 7/16″–3 3/4″ | ● | ● |

| 88 | 92–100 | 3 5/8″–3 15/16″ | ● | ● |

| 94 | 97–105 | 3 13/16″–4 1/8″ | ● | ● |

| 100 | 102–110 | 4″–4 5/16″ | ● | ● |

| 108 | 108–116 | 4 1/4″–4 9/16″ | ● | ● |

| 116 | 114–122 | 4 1/2″–4 13/16″ | ● | ● |

| 124 | 121–129 | 4 3/4″–5 1/16″ | ● | ● |

| 132 | 127–135 | 5″–5 5/16″ | ● | ● |

| 140 | 134–142 | 5 1/4″–5 9/16″ | ● | ● |

| 148 | 140–148 | 5 1/2″–5 13/16″ | ● | ● |

HWKG provides following T-blot clamps

T-type constant pressure clamp

T-type high constant pressure clamp

T-type vibration damping clamps with brackets

T-type open clamp

Key features of T-bolt clamp

HWKG T-bolt clamps are designed for demanding applications, providing a secure and durable solution for hoses, pipes, and tubing. The have following features:

Strong Grip and Secure Fastening

T-bolt clamps clamps provide a firm, secure grip around silicone hoses, rubber tubing, and metal pipes. The T-shaped bolt ensures maximum clamping force, keeping hoses tightly fastened under high-pressure conditions. These clamps prevent slippage, leaks, and blowouts, making them ideal for automotive turbo systems, cooling lines, and hydraulic applications.

High-Strength Construction

T-bolt hose clamps are usually manufactured from premium stainless steel, offering excellent corrosion resistance, rust prevention, and long-term durability. T-bolt clamps maintain their shape and performance in marine, industrial, etc. The reinforced metal body and sturdy bolt make them suitable for repeated use, high-stress conditions, and extreme temperature variations without compromising clamping integrity.

Even Pressure Distribution

T-bolt clamps are engineered to distribute clamping pressure evenly around the hose or pipe. This prevents stress concentration, hose deformation, or surface damage, which is especially important for delicate silicone hoses or rubber tubing. By providing uniform pressure, T-bolt clamps minimize the risk of leaks, ensure a tight seal, and extend the service life of both hoses and connected components.

Durable in Extreme Conditions

T clamps are designed to withstand harsh environments, including vibration, mechanical stress, high temperatures, and thermal expansion. They maintain performance in automotive turbochargers, industrial machinery, marine engines, and other high-demand applications. Their combination of corrosion resistance, and vibration tolerance makes them a reliable choice.

What are T clamps used for?

HWKG’s T-bolt can be widely used in various scenarios, ensuring high quality and high performance.

Marine and offshore applications

In marine and offshore systems, corrosion resistance and durability are essential. T-bolt clamps ( often made from 300 series stainless steel ) are used to secure cooling, exhaust, and bilge hoses exposed to saltwater. Their robust construction prevents loosening from vibration and ensures a tight seal even under constant pressure and moisture exposure.

Industrial Manufacturing and Equipment

Heavy-duty T-bolt clamps secure high-pressure hoses, ducting, and ventilation systems. They provide uniform clamping force and resist loosening caused by vibration or temperature cycling. These clamps are common in pneumatic systems, dust collection ducts, and hydraulic lines where reliability and safety are priorities.

Automotive and Heavy-Duty Vehicles

T-bolt clamps play a vital role in securing turbocharger, radiator, and exhaust hoses. Their high tensile strength allows them to withstand intense vibration and temperature changes in engine bays. Especially in commercial trucks, construction machinery, and performance cars, they prevent boost leaks and ensure reliable air and fluid transfer.

Agricultural and Irrigation Systems

In agricultural irrigation, T-bolt hose clamps are used to connect water hoses and pipelines under variable pressure conditions. Their corrosion-resistant stainless steel construction ensures long-lasting performance even in humid, muddy, or outdoor environments. These clamps minimize leakage and water loss, helping maintain efficient irrigation flow.

Need a different clamp option? Connect with our product expert for the most recent catalog.

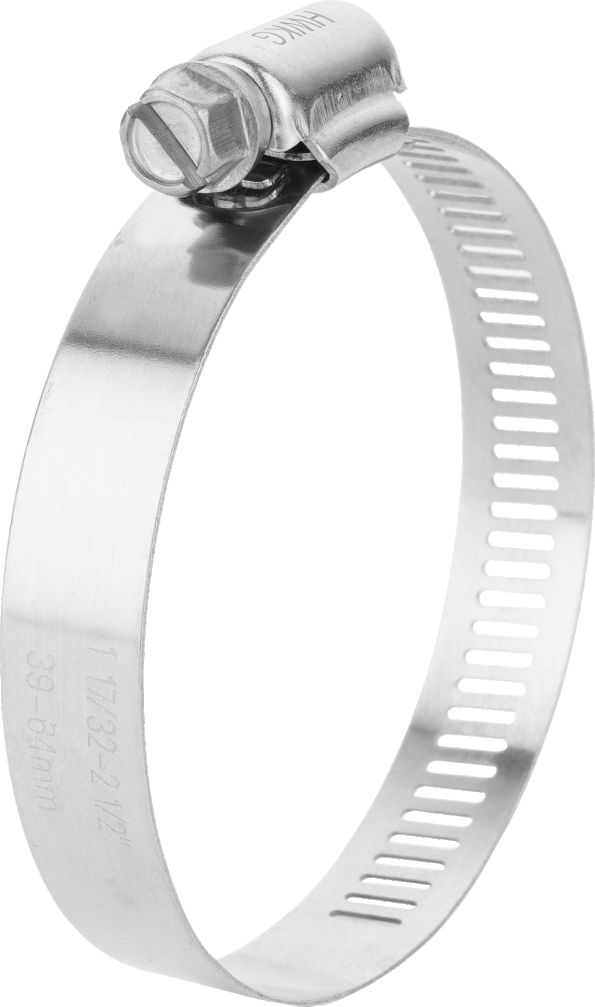

Are T-bolt clamps better than worm gear clamps?

HWKG offers both high-quality T-bolt clamps and worm drive clamps, when and how to choose them is crucial to your project.

When to Use T-Bolt Clamps

T-bolt clamps are the preferred choice for high-pressure or heavy-duty applications where strength, stability, and durability are critical. They provide a secure and uniform seal, even under extreme vibration or temperature fluctuations, making them ideal for automotive turbo systems, industrial machinery, and marine engines. While slightly more expensive than worm drive clamps, they deliver long-term reliability and are well suited for professional or high-performance environments.

When to use worm drive clamps

Worm drive clamps, also known as worm gear hose clamps, are versatile, adjustable, and cost-effective solutions. They are widely used for automotive hoses, plumbing, garden irrigation systems, and general-purpose pipe connections. Stainless steel or galvanized worm drive clamps provide corrosion resistance while offering secure fastening. They are easy to install and remove with a screwdriver, making them convenient for routine maintenance, or applications where frequent adjustments may be required.

The best choice depends on the material, pressure requirements, hose or pipe type, and the specific operating environment. Selecting high-quality stainless steel hose clamps, properly sized for your application, will ensure reliable performance and long-lasting results.

Why choose HWKG as your T-bolt clamp supplier?

HWKG is your reliable partner for T-bolt clamps, we deliver dependable solutions for customers worldwide. When you choose HWKG, you can expect:

Comprehensive Certifications

HWKG holds several invention and utility patents, certified to ISO9001, IATF16949, ISO14001, ISO45001, and CUPC, and operates an upgraded ERP system for efficient management.

R&D Team with Innovation

Our R&D team continues to advance along the Industry 4.0 path, focusing on 3D virtual modeling, simulation, digitalization, information integration, etc.

Strict Quality Control and Certification

Advanced testing equipment and standardized procedures ensure every product meets high-performance and reliability standards.

Advanced Manufacturing

HWKG combines modern production facilities, skilled workforce, and precision equipment to ensure efficient manufacturing and consistent product quality.

Integrated Customer Solutions

We provides complete solutions covering cost, efficiency, and quality, offering seamless one-stop services from R&D and production to sales and after-sales support.

T-Bolt Hose Clamp FAQ Guide

Do T bolt clamps prevent leaks?

Yes, T-bolt clamps help prevent leaks by applying strong and even pressure around the hose connection. Their heavy-duty design ensures a tight, uniform seal that minimizes the risk of leaks under high pressure or vibration.

Are T-bolt clamps reusable?

Yes, T-bolt clamps are reusable if they remain undamaged. Before reusing, inspect the stainless T-bolt clamp for corrosion, stripped threads, or deformation. As long as it can still tighten evenly and hold a firm seal, it can be safely reused. Replace it if the bolt or band shows wear or rust to ensure reliable performance.

How tight should a T bolt clamp be?

A T-bolt clamp should be tightened just enough to create a secure, leak-free seal without deforming the hose. Generally, 25–50 in-lbs of torque is recommended, though 30–45 in-lbs suits most stainless T-bolt clamps.

How do you measure for a T bolt clamp?

To size a T-bolt hose clamp correctly, measure the outer diameter (OD) of the hose after it’s fitted onto the pipe or fitting. Use a caliper or tape measure, making sure the hose isn’t compressed or deformed. Then, select a T-bolt clamp whose adjustable range includes your measured OD—ideally one slightly larger than the hose diameter. If the size falls between two options, choose the larger clamp for proper fit and even tension.