Worm Drive Clamp Manufacturer And Supplier

We provide a wide range of sizes along with customizable options to meet different hose and pipe requirements. Each clamp is manufactured from advanced production technology, ensuring exceptional durability and reliable strength under demanding conditions.

What is worm drive clamp?

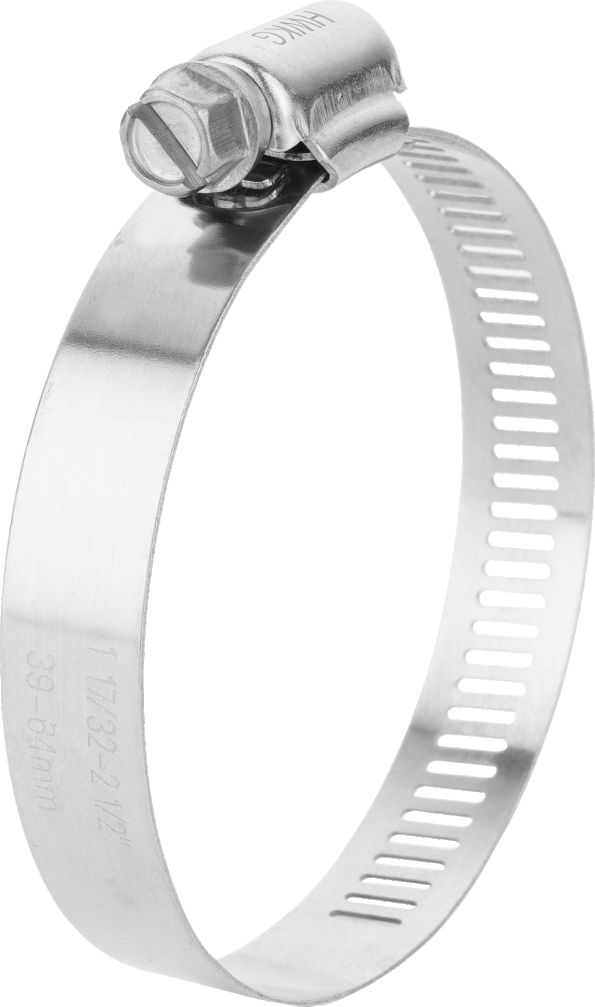

A worm drive clamp, also known as a worm gear hose clamp, is a versatile fastening device designed to securely attach hoses onto fittings such as pipes or tubes. It is constructed with a durable metal band featuring a screw thread pattern and a captive screw mechanism. When the screw is rotated, the worm gear engages with the band’s slots, causing the band to contract evenly around the hose. This uniform tightening action distributes pressure consistently, preventing leaks and ensuring a reliable connection without damaging the hose surface.

Key Features of Worm Drive Clamp

Versatile Applications

Worm drive clamps can be adjusted to fit a wide range of hose sizes and materials. Their flexibility allows one clamp type to serve multiple purposes with reliable performance.

Durable Materials

Made from stainless steel or carbon steel, worm drive clamps are built to last. Stainless steel options provide excellent corrosion resistance for long-term performance.

Easy Installation

Worm drive clamps are designed for quick and simple use. With just a screwdriver or socket tool, they can be tightened or loosened easily for fast setup and adjustments.

Vibration Resistant

The design applies even pressure around the hose, ensuring a firm seal. This prevents loosening caused by vibration and helps protect against leaks.

Types of Worm Drive Hose Clamps We Manufacture

Need a different clamp option? Connect with our product expert for the most recent catalog.

Difference between American, German and British type worm drive clamps

American style relies on a straightforward screw-and-band structure. It’s easy to operate with a regular screwdriver and can be fitted quickly even in tight spaces. Because of its simple mechanism, it is often chosen for everyday systems where a fast and reliable connection is more important than heavy-duty sealing.

German type clamps feature a continuous band with evenly distributed teeth, allowing consistent pressure around the hose. Installation may take slightly longer, but the secure fit resists vibration and prevents leaks. They are widely adopted in automotive and mechanical systems that face demanding or high-pressure environments, where performance and safety are a priority.

British style clamps typically use a smooth band that applies torque evenly, minimizing the risk of damaging softer hoses. They are simple to use yet offer stable performance, making them suitable for general-purpose connections in fluid transfer, irrigation setups, and other routine applications where balance and efficiency matter.

Why choose HWKG as your worm drive clamp supplier?

HWKG is your reliable partner for worm drive hose clamps, we deliver dependable solutions for customers worldwide. When you choose HWKG, you can expect:

Comprehensive Certifications

HWKG products meet global standards with certifications such as ISO9001, IATF16949, ISO14001, ISO45001, and CUPC, guaranteeing reliable quality and compliance.

Over 20 Years Of Expertise

With over 20 years of expertise, HWKG has evolved into a trusted clamp manufacturer, distinguished by its independent design and ongoing innovation.

Strong R&D And Technical Team

Our in-house team of 50+ engineers and technicians enables rapid product development, customized solutions, and support tailored to diverse industries.

Automated Production

We operate modern, automated production lines and ERP management systems, ensuring efficiency, consistency, and large-scale manufacturing capacity..

High Quality Control & Testing

Our laboratory is equipped with advanced instruments to verify performance under real conditions. Every product undergoes strict inspection to ensure quality.

What is a worm drive clamp used for

Automotive & Vehicles

Worm drive clamps are widely used in vehicles to secure hoses carrying fluids like coolant, air, and fuel. Their adjustable design ensures a tight and reliable seal under pressure.

Industrial & Manufacturing

In factories and machinery, worm drive clamps hold pipes and hoses in place for air, water, and chemical transfer. Their durability makes them ideal for demanding production environments.

Agriculture & Irrigation

These clamps are used to connect hoses and pipes in irrigation systems and farm equipment. They provide consistent sealing performance even in outdoor, high-moisture conditions.

Marine & Shipbuilding

Worm drive clamps are widely used in vehicles to secure hoses carrying fluids like coolant, air, and fuel. Their adjustable design ensures a tight and reliable seal under pressure.

Home & Garden

For household projects, worm drive clamps are commonly used in plumbing repairs, gardening systems, and DIY tasks. Their ease of installation makes them practical for everyday use.

Material types of Worm Drive Hose Clamp

A worm gear hose clamp may use multiple materials in one design to balance strength, flexibility, and resistance to wear. Choosing the right material combination is essential to match the specific application, ensuring reliable performance across automotive, industrial, household, and hardware uses.

200 series stainless steel worm drive clamp

200 series stainless steel worm drive clamps are made with an austenitic alloy containing more manganese and nitrogen, but less nickel. This composition gives the clamp higher strength and hardness while maintaining good toughness, even under low temperatures. Although corrosion resistance is weaker compared to 300 series, these clamps provide reliable fastening where strength are key.

300 series stainless steel worm drive clamp

The 300 series stainless steel, such as 304 and 316, is the most widely used stainless steel type. Known for excellent corrosion resistance, heat resistance, and formability, clamps made from 300 series perform well in both high and low temperature environments. This makes them the most reliable choice for long-term durability and demanding conditions.

400 series stainless steel worm drive clamp

400 series stainless steel feature high chromium content and lower nickel, giving them strong wear resistance, oxidation resistance, and mechanical strength. While their corrosion resistance is lower than 300 series, they deliver excellent clamping force and durability. This balance makes 400 series clamps a practical solution for environments where strength is more important than chemical resistance.

carbon steel worm drive clamp

Carbon steel worm drive clamps are valued for their high tensile strength and affordability. With protective surface treatments, they provide a strong and secure connection.

Worm Drive Clamps FAQ

How to install and tighten worm drive clamps?

- Position the clamp – Slide the clamp onto the hose and place it about 6 mm from the hose end.

- Attach the hose – Push the hose fully onto the fitting without twists or gaps.

- Tighten the screw – Use a screwdriver or socket to turn the screw clockwise until snug. Avoid over-tightening, which can deform the hose.

- Check the seal – Run the system or perform a quick pressure test to confirm there are no leaks.

How to choose the right worm drive clamp?

- Match the Hose Material

- Choose the Right Size

- Consider Environmental Conditions

- Check Industry Standards

Is a worm drive clamp adjustable?

worm drive clamps are fully adjustable. They feature a slotted band and a screw mechanism that allows the band to expand or contract to match different hose diameters. By turning the screw with a screwdriver, you can easily tighten or loosen the clamp to achieve a secure and precise fit.

How does a worm drive clamp work?

A worm drive clamp works by using a screw-and-gear mechanism to tighten the band around a hose. When you turn the screw, the worm gear engages with the band’s slots, pulling it tighter in a uniform circle. This creates even pressure around the hose and fitting, forming a secure, leak-resistant seal. Turning the screw in the opposite direction releases the pressure and loosens the clamp.

What is the difference between worm T-Bolt clamp and drive clamp

T-Bolt clamps are built for heavy-duty use. They deliver strong, even pressure around large hoses and hold up well under high pressure, heat, and vibration—common in turbo systems, hydraulic lines, and industrial machinery.

Worm drive clamps, by contrast, are lighter and more versatile. They tighten with a screw, are easy to install in tight spaces, and fit a wide range of hose sizes. They’re ideal for plumbing, automotive repairs, and other light to medium-duty jobs.

What is the difference between spring clamp and a worm clamp?

A worm clamp uses a screw for adjustable tightness, making it versatile but prone to loosening or damaging soft hoses if over-tightened.

A spring clamp relies on constant spring tension, offering less adjustability but better long-term grip and gentler contact with hoses.

How to maintain worm drive clamps?

Regularly inspect your clamp for rust, dirt, or damage. Lubricate the screw for smooth operation, clean off debris, and replace if cracked or corroded. Check tightness from time to time and readjust to keep a secure seal.