cushion clamp manufacturer and supplier

Compliant with the DIN 3016-1

A cushion clamp, also known as a rubber P clamp or rubber cable clamp, is a versatile fastening device designed to secure pipes, hoses, and cables while minimizing vibration and abrasion. Its rubber lining provides a cushioned grip that protects against wear and heat damage, ensuring stability even in demanding environments. Commonly used in automotive, electrical, and mechanical applications, these P clamps offer both reliable support and noise reduction for smooth, long-term operation.

We provide a wide range of sizes along with customizable options to meet different hose and pipe requirements. Each clamp is manufactured from advanced production technology, ensuring exceptional durability and reliable strength under demanding conditions.

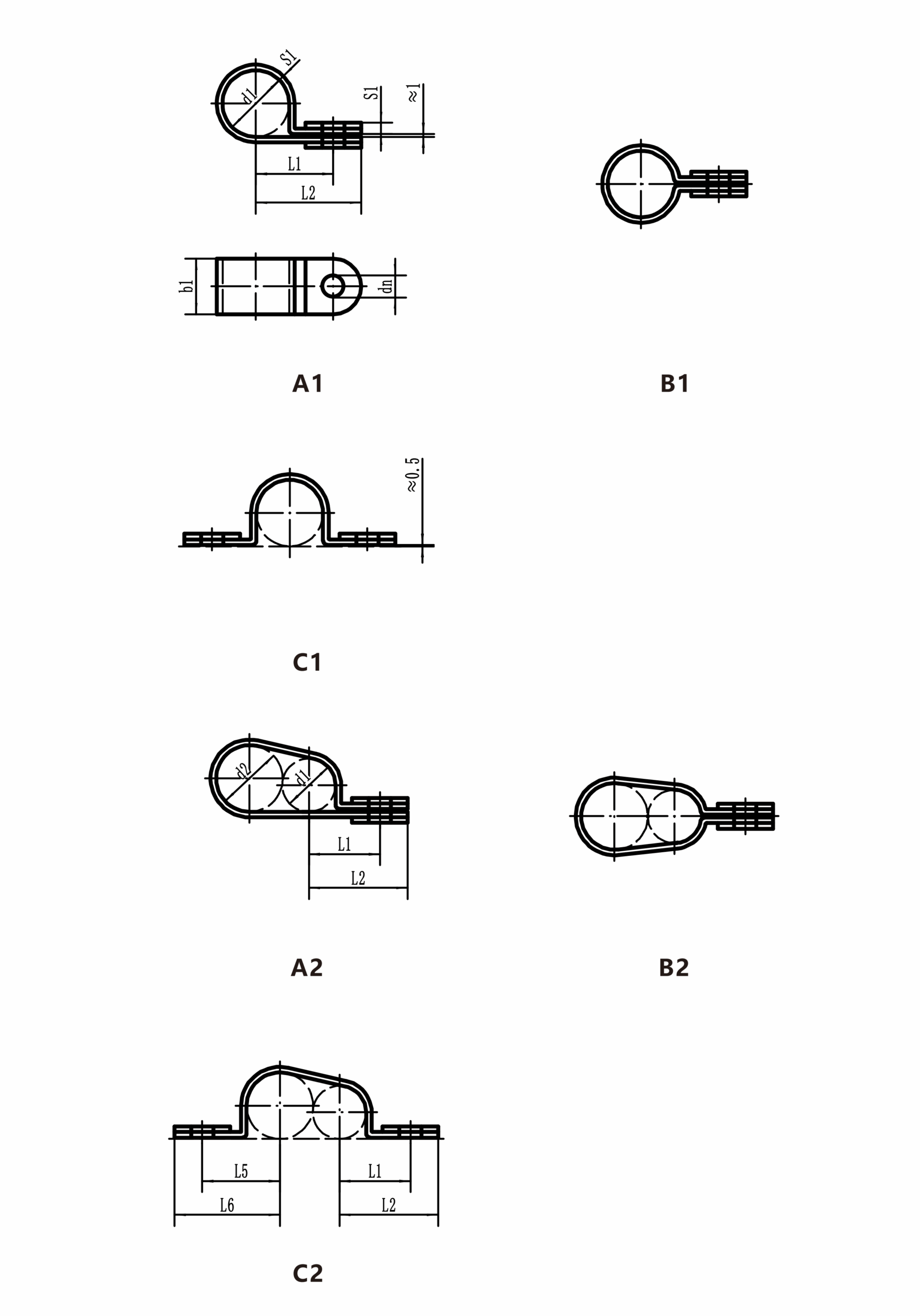

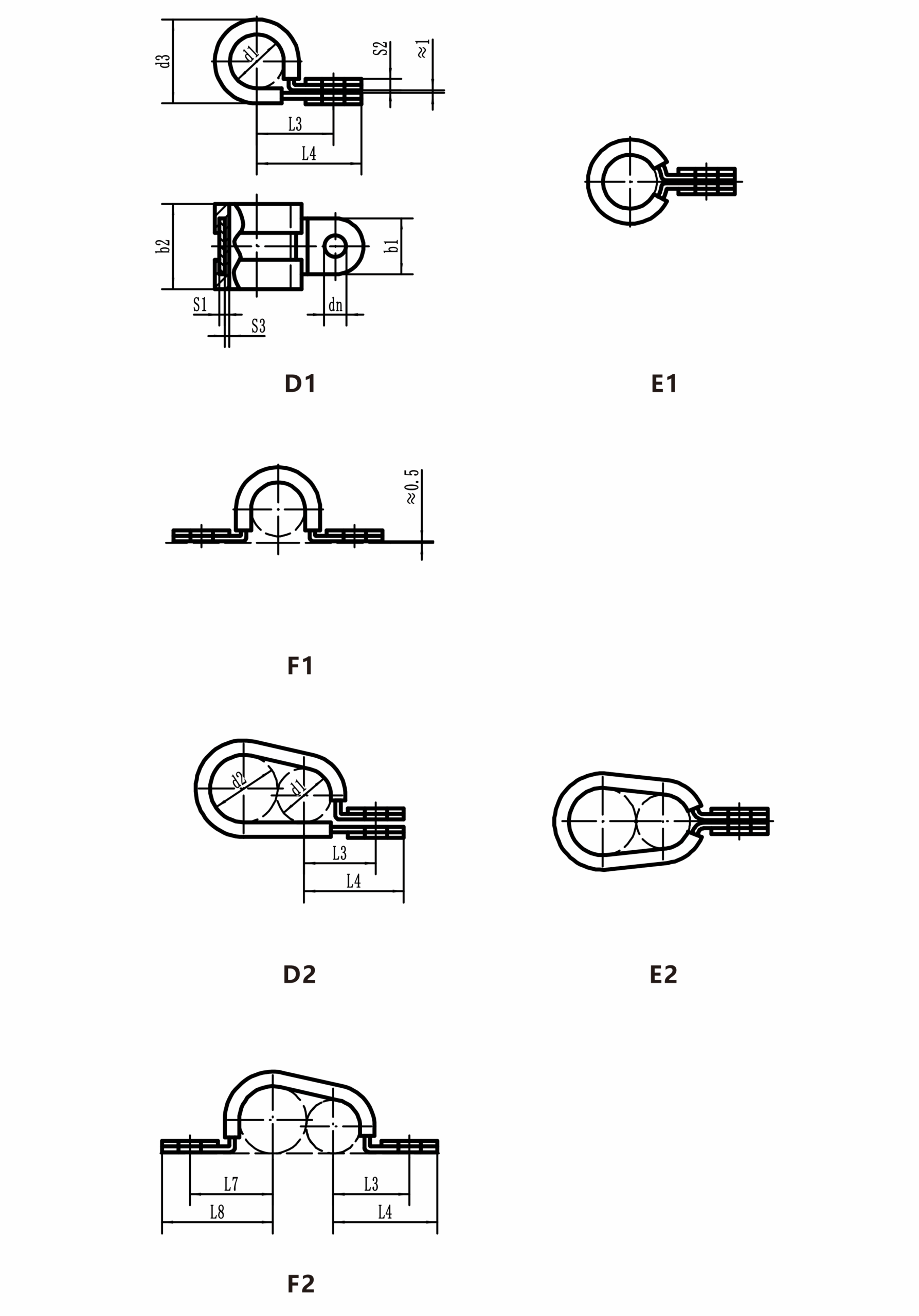

HWKG provides the following cushion clamps

D2 cushion clamps

F1 cushion clamps

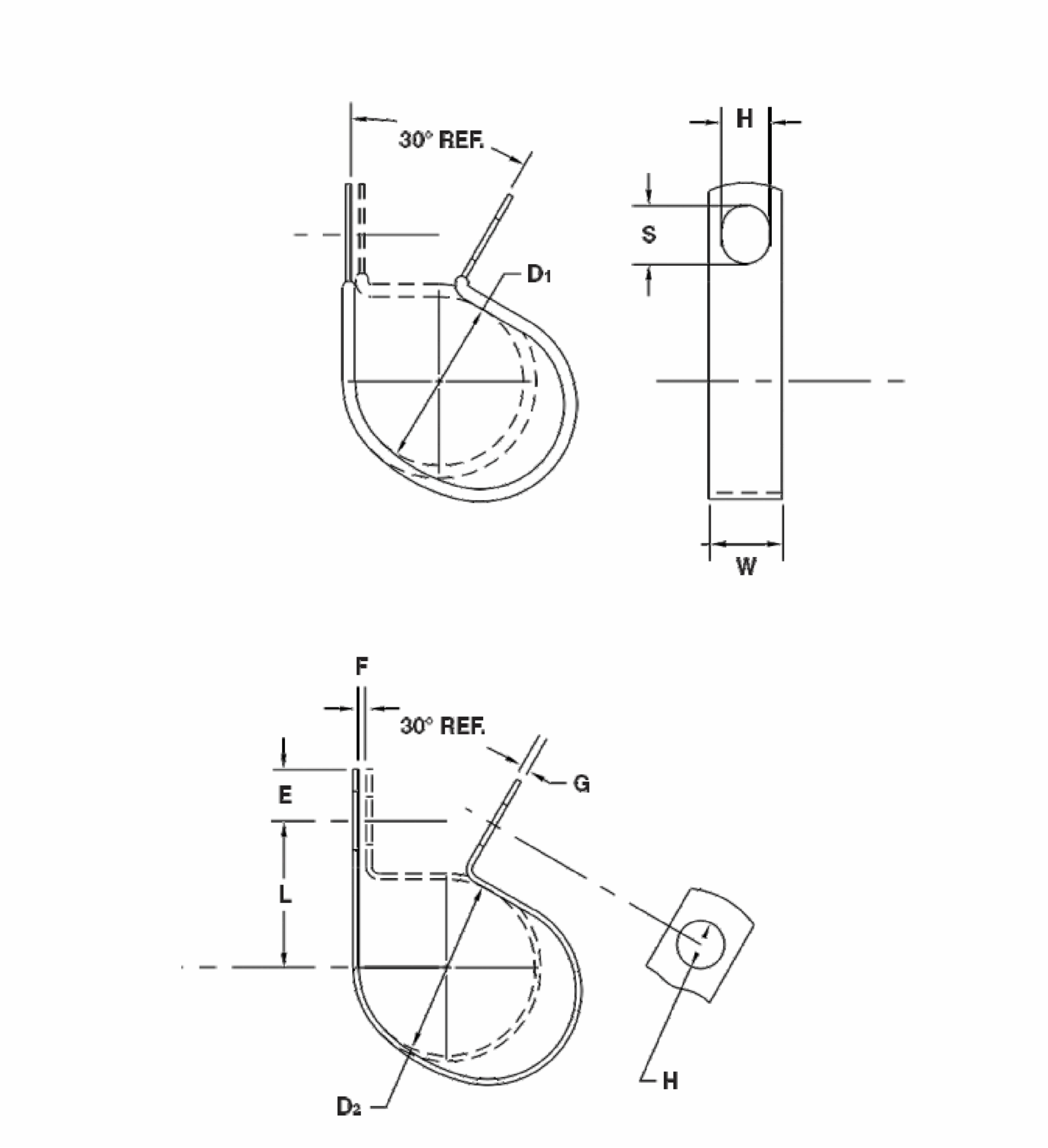

Rivetless cushion clamp with adhesive strip

Rivetless dip-coated cushion clamps

Rivetless cushion clamps

Surface options

Zinc plating: Aesthetically pleasing; accessories can withstand neutral salt spray tests for 24/48/72 hours without red rust.

Dacromet plating: Accessories can withstand neutral salt spray tests for 120-1000 hours without red rust.

EPDM rubber strips: Temperature resistance -40℃~120℃.

Silicone rubber strips: Temperature resistance -40℃~250℃.

Cushion Clamp ( Fix Clamp ) Specification Table

| Clamping range | Bandwidth | b2 | dn | d3 | L1 L3 +1/-0.02 | L2 L4 max | L7 +1/-0.2 | L8 max | S1 + 0.2/-0.1 W1 W4 / W5 | S2 + 0.2/-0.1 W1 W4 / W6 | S3 ±0.35 | Strip material | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4–20 | 9 | 13±0.8 | 4.3 | d1+ | 5.2 | d1/2+ | 5.7 | d1/2+ | 10.2 | d1/2+ | 5.7 | d1/2+ | 10.2 | 0.4 | 1.4 | 1 | EPDM, Chloroprene Rubber, PVC and other materials option available | ||

| 4–25 | 12 | 15±0.8 | 5.3 | 5.8 | 8 | 14 | 8 | 14 | 0.5 | 0.5 | 1.2 | ||||||||

| 5–14 | 15 | 19±1.0 | 6.4 | 11.2 | 11.2 | 18.7 | 11.2 | 18.7 | 0.6 | 0.6 | 1.5 | ||||||||

| 15–45 | 0.8 | 0.6 | 1.8 | 1.6 | |||||||||||||||

| 10–25 | 20 | 25±1.0 | 8.4 | 14.5 | 14.5 | 24.5 | 14.5 | 24.5 | 0.8 | 2.3 | 2 | ||||||||

| 26–50 | 1 | 0.8 | 2.5 | 2.3 | |||||||||||||||

| 15–49 | 25 | 31±1.3 | 10.5 | 17.5 | 17.5 | 30 | 17.5 | 30 | 1 | 2.5 | 3 | ||||||||

| 50–150 | 1.25 | 1 | 2.75 | 2.5 | |||||||||||||||

| D1 | D2 | H | L | W | E | F | G | S | Steel strip material | Rubber strip material |

|---|---|---|---|---|---|---|---|---|---|---|

| .125 | .187 | .281 | .468 | .500 | .312 | .031 | .032 | .375 | This product offers material options such as hot-dip galvanized steel strip, galvanized carbon steel, and 300 series stainless steel to meet different application requirements | PVC |

| .343 | .531 | .625 | .375 | .031 | .032 | .437 | ||||

| .406 | .593 | .750 | .437 | .031 | .032 | .500 | ||||

| .187 | .250 | .281 | .500 | .500 | .312 | .031 | .032 | .375 | ||

| .343 | .562 | .625 | .375 | .031 | .032 | .437 | ||||

| .406 | .625 | .750 | .437 | .031 | .032 | .500 | ||||

| .468 | .687 | .750 | .500 | .031 | .032 | .562 | ||||

| .250 | .312 | .281 | .531 | .500 | .312 | .031 | .032 | .375 | ||

| .343 | .593 | .625 | .375 | .031 | .032 | .437 | ||||

| .406 | .656 | .750 | .437 | .031 | .032 | .500 | ||||

| .468 | .718 | .750 | .500 | .031 | .032 | .562 | ||||

| .531 | .781 | .875 | .562 | .031 | .032 | .625 | ||||

| .312 | .375 | .281 | .562 | .500 | .312 | .031 | .032 | .375 | ||

| .343 | .625 | .625 | .375 | .031 | .032 | .437 | ||||

| .406 | .687 | .750 | .437 | .031 | .032 | .500 | ||||

| .468 | .750 | .750 | .500 | .031 | .032 | .562 | ||||

| .531 | .812 | .875 | .562 | .031 | .032 | .625 | ||||

| .375 | .437 | .281 | .593 | .500 | .312 | .062 | .032 | .375 | ||

| .343 | .656 | .625 | .375 | .062 | .032 | .437 | ||||

| .406 | .718 | .750 | .437 | .062 | .032 | .500 | ||||

| .468 | .781 | .875 | .500 | .062 | .032 | .562 | ||||

| .531 | .843 | .875 | .562 | .062 | .032 | .625 | ||||

| .437 | .500 | .281 | .625 | .500 | .312 | .062 | .048 | .375 | ||

| .343 | .687 | .625 | .375 | .062 | .048 | .437 | ||||

| .406 | .750 | .750 | .437 | .062 | .048 | .500 | ||||

| .468 | .812 | .875 | .500 | .062 | .048 | .562 | ||||

| .531 | .875 | 1.000 | .562 | .062 | .048 | .625 | ||||

| .500 | .562 | .281 | .656 | .500 | .312 | .062 | .048 | .375 | ||

| .343 | .718 | .625 | .375 | .062 | .048 | .437 | ||||

| .406 | .781 | .750 | .437 | .062 | .048 | .500 | ||||

| .468 | .843 | .875 | .500 | .062 | .048 | .562 | ||||

| .531 | .906 | 1.000 | .562 | .062 | .048 | .625 | ||||

| .562 | .625 | .281 | .687 | .500 | .312 | .062 | .048 | .375 | ||

| .343 | .750 | .625 | .375 | .062 | .048 | .437 | ||||

| .406 | .812 | .750 | .437 | .062 | .048 | .500 | ||||

| .468 | .875 | .875 | .500 | .062 | .048 | .562 | ||||

| .531 | .937 | 1.000 | .562 | .062 | .048 | .625 |

What are the benefits of using P clamps ?

HWKG cushion clamps, combine a strong metal body with a resilient rubber lining, offering vibration damping, abrasion protection, and secure support for pipes, hoses, and cables.

Vibration and Noise Reduction

Rubber lined P clamps, also known as cushion clamps, are excellent at absorbing vibration and minimizing noise. The soft rubber lining creates a buffer between the clamp and the secured item, preventing metal-to-metal contact. This reduces mechanical fatigue and ensures smoother operation for pipes, cables, and hoses in automotive and industrial environments.

Protection Against Abrasion and Wear

A key advantage of rubber P clamps is their ability to prevent abrasion. The cushion layer protects hoses and cables from damage caused by friction or constant movement. This is particularly important for flexible tubing or electrical harnesses where insulation or surface integrity must remain intact.

Corrosion and Thermal Protection

Rubber lined cushion clamps also help isolate dissimilar metals, reducing the risk of galvanic corrosion. In addition, the rubber lining accommodates minor thermal expansion and contraction, preventing cracks or breaks in both the clamp and the object being secured. This makes them suitable for harsh outdoor or marine environments.

Secure, Versatile Mounting Solution

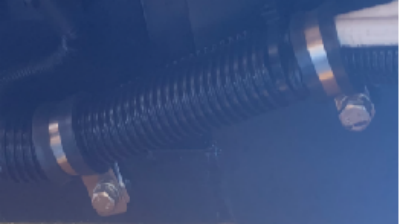

Cushion clamps are easy to install and come in various materials and sizes, such as stainless steel, aluminum, and galvanized steel. Whether used for securing hydraulic hoses, wiring bundles, or conduit tubes, their durable rubber cushion provides a stable and long-lasting hold under vibration, heat, or movement.

What are cushion clamps used for?

Cushion clamps are versatile fastening solutions used to secure hoses, pipes, and cables. HWKG’s cushion clamps are widely applied across various industries thanks to their durable rubber lining and reliable performance. Below are some common uses for these clamps:

Cushion Clamps for Automotive

Rubber P clamps are widely used in automotive applications to secure wiring harnesses, hoses, and tubing. Their cushion lining reduces vibration and protects components from abrasion, ensuring reliable performance in engines and chassis systems.

Cushion Clamps for Marine

In marine environments, cushion clamps help fasten cables, pipes, and hoses while resisting corrosion and vibration. The rubber lining absorbs shock and prevents wear, making them ideal for boats, ships, and offshore equipment.

Cushion Clamps for Industrial Equipment

Cushion clamps provide stable mounting for machinery wiring, hydraulic hoses, and piping. Their durable rubber lining protects components from friction and vibration, improving safety and extending equipment lifespan in factories and plants.

Cushion Clamps for Plumbing and Piping

Rubber lined P clamps are perfect for plumbing and piping systems, keeping pipes secure and preventing abrasion. They accommodate thermal expansion and vibration, ensuring leak-free and long-lasting installations.

Need a different clamp option? Connect with our product expert for the most recent catalog.

Common material types of cable clamp

HWKG offers metal cable clamps in various materials to suit different applications, such as hot-dip galvanized steel strip, galvanized carbon steel, and 300 series stainless steel. Some clamps even combine materials for optimal strength and protection.

Stainless Steel Cable Clamp

Stainless steel cable clamps, made from hot-dip galvanized steel strip, galvanized carbon steel, or 300 series stainless steel, provide superior strength and corrosion resistance. These clamps are ideal for harsh industrial or automotive environments, offering long-term durability while securely holding hoses, pipes, or cables. The rigid metal construction ensures that the clamp maintains its shape under high stress, while still accommodating minor movements when used with rubber lined versions.

Rubber Cable Clamp

Rubber P clamps or rubber lined cushion clamps are designed for vibration damping and abrasion protection. The soft PVC or rubber lining prevents wear on hoses, tubing, and wiring bundles, extending their lifespan and ensuring a secure grip. These clamps are perfect for applications requiring delicate handling of materials, such as copper tubing, plastic pipes, or electrical cables, while still providing firm attachment to walls, ceilings, or other mounting surfaces.

Aluminum P Clamp

Aluminum P clamps combine lightweight design with moderate strength and corrosion resistance. These clamps are suitable for applications where weight reduction is important without sacrificing stability. The metal provides a solid structure, while some designs incorporate rubber lining to protect sensitive hoses or wiring. Aluminum P clamps are commonly used in automotive, marine, and machinery installations where both durability and reduced weight are essential.

Why choose HWKG as your cushion clamp supplier?

HWKG is your reliable partner for cushion clamps, we deliver dependable solutions for customers worldwide. When you choose HWKG, you can expect:

More Than 20 Years Experience

HWKG has specialized in clamp manufacturing for over 20 years, providing reliable products and professional solutions to global customers.

Industry-Leading R&D Capability

We have a professional R&D team of over 50 experts, combining design innovation with manufacturing excellence to develop advanced clamp solutions.

Strict Quality Control and Management

We ensure consistent quality through advanced equipment, in-house automation, and ISO9001, ISO14001, ISO45001, and IATF16949 certified management systems.

Broad Field of Application

HWKG products are widely used across diverse industries, including automotive, power systems, telecommunications, security, marine, power tools, etc.

Comprehensive Service for Customer

We provide professional pre-sale consultation, technical assistance, and after-sales service to ensure every customer receives timely response, reliable solutions.

Cushion Clamps FAQ

Are cushion clamps reusable?

Yes, many types of cushion clamps are reusable, especially those made from high-quality materials like stainless steel, as long as they are not damaged during removal. However, some specialized clamps, such as certain types for fiber optic cables or specific one-time-use applications, may not be reusable.

Can P clamps be used on hoses?

Yes, P clamps, especially rubber P clamps, are designed to be used on hoses to securely fasten them while protecting against abrasion and vibration. They are widely used in industries like automotive and marine for applications such as mounting fuel and hydraulic lines.

Are P clips resistant to corrosion?

Yes, P clips can be corrosion-resistant, with resistance depending on the material they are made from, such as stainless steel, nylon, or specialized coatings. Stainless steel (like 304 or 316) and nylon clips offer excellent corrosion resistance, while mild steel clips may have coatings like zinc plating to protect against rust. For the best protection, particularly in harsh environments, stainless steel P clamps are the most reliable options.

How to use rubber P clamps?

To use a rubber P clamp, first select a clamp suitable for your wire, cable, or hose. Place the item into the circular opening of the clamp, ensuring it sits securely on the rubber lining. Position the clamp on the wall, ceiling, or other mounting surface, then tighten it with a screw to hold the item firmly in place. Ensure the clamp is snug but not overly tight, allowing the rubber lining to absorb vibration and protect the cable or hose from abrasion.