Flexible PVC connectors join two pipes and allow them to move. This makes pipe repair easier. HWKG is a top company that provides robust and reliable products. Their products prevent leaks and absorb pipe vibrations. Many businesses use these connectors. They help ensure the safe operation of piping systems and plant systems.

- Flexible pipe coupling provide a tight seal and reduce stress caused by pipe movement.

- PVC material accounts for over 80% of the market share in water systems.

Key Takeaways

- Flexible PVC connectors connect pipes and allow them to move. This helps prevent leaks and reduces pipe stress.

- These connectors are made from strong and durable materials such as PVC and rubber. They do not rust and are resistant to chemicals and temperature changes.

- Installation is quick and easy, requiring no special tools. Anyone can easily repair or connect pipes in minutes.

Flexible PVC Coupling Features

Durability and Flexibility

Each HWKG flexible PVC connector is made from strong, elastomeric materials. These materials use PVC, which is flexible and does not rust. They also use rubbers such as EPDM or NBR, which have good tensile strength and are resistant to chemicals. These properties help the connectors last a long time, even in harsh environments.

- PVC is flexible and does not rust, making it suitable for home plumbing systems.

- EPDM and NBR rubber have better tensile strength and are resistant to high and low temperatures and chemicals. This is ideal for factories and large construction sites.

HWKG products have important certifications such as CUPC and ASTM C1173. These certifications indicate that the connectors are safe and of high quality.

| Certification | Description |

|---|---|

| CUPC | Canadian Uniform Plumbing Code compliance |

| ASTM C1173 | Standard for flexible PVC couplings |

Engineers test these connectors in the lab to ensure their strength and durability. In bending fatigue tests, high-quality connectors maintain their shape after 50,000 bends. Lower-quality connectors fail sooner. Pressure and vacuum tests show that HWKG connectors remain stable when pipes move or pressure changes.

| Test Type | Description | Outcome |

|---|---|---|

| Bending Fatigue Test | Hose bent ±180° thousands of times with air flow | Durable materials last 50,000 cycles; low-grade fails at 5,000 |

| Pressure and Vacuum | Simulate suction and back-pressure | Reinforced designs stay stable within ±5% |

| Chemical and Abrasion | Tested against detergents, sand, and oils | Minimal swelling or wear after 10,000 cycles |

Leak Prevention and Vibration Absorption

Flexible PVC connectors allow pipes to move without breaking the seal, effectively preventing leaks. This design allows the connector to accommodate slight bending and displacement of the pipe. This is important because pipes can shift due to thermal expansion and contraction or ground movement.

- The connector allows for slight pipe movement, preventing leaks.

- Its special shape provides a tight fit, effectively preventing water or other fluid leaks.

- The housing allows for slight movement of the pipe ends, ensuring a secure connection.

Flexible PVC connectors also absorb vibrations. When machines or pumps vibrate, the internal soft gasket acts as a cushion. This gasket breaks down the vibrations and converts them into a small amount of heat. This protects the pipes and connectors from damage.

The flexible connector acts as a vibration damper. The elastomer gasket does not easily transmit vibrations. When vibrations impact the connector, the soft gasket causes molecular movement, converting the vibration into internal heat, resulting in less impact on the pipe.

Tests at NASA’s Vibration and Acoustics Test Facility have shown that flexible connectors provide better vibration damping than some other connectors. This helps extend the lifespan of the piping.

Material Compatibility

Flexible PVC couplings are suitable for a variety of pipes. They can connect PVC, cast iron, steel, and copper pipes. This makes them suitable for both home and large-scale engineering projects.

- PVC couplings also perform well in environments where chemicals such as sodium carbonate or potassium carbonate are present.

- With proper installation and maintenance, the couplings can last longer, even in chemical environments.

- These couplings are resistant to many chemicals, sunlight, and bacteria.

| Feature | Flexible PVC Couplings | Rigid Pipe Couplings |

|---|---|---|

| Movement | Allows movement | No movement |

| Pipe-end Separation | Yes | No |

| Joint Type | Flexible, sealed | Rigid, no flexibility |

| Support Requirements | More complex | Similar to welding |

These couplings can bend slightly if the pipes are not straight. This helps the system function properly even if the pipes shift over time.

Uses, Installation, and Selection

Common Applications

Flexible PVC couplings are versatile in piping systems. People use these couplings in homes, factories, and farms. They help connect pipes in new construction. They can also be used to repair old or damaged pipes. Workers choose them for the following reasons:

- Residential plumbing: People use them to connect pipes under sinks, in basements, or behind walls.

- Industrial piping: Factories use them for process lines, drains, and sewer lines.

- Irrigation systems: Farmers and landscapers use them to connect pipes in fields and gardens.

- Pipe repair: Plumbers use them to quickly repair leaks or replace damaged pipe sections.

- Bypassing obstacles: Installers use them when pipes need to bend or go around obstacles.

These couplings are suitable for a variety of pipe types, such as PVC, cast iron, steel, and copper. Their flexibility helps accommodate pipe movement or settlement over time.

Installation Steps

Installing flexible PVC couplings is quick and easy. The couplings manufactured by HWKG do not require special tools. Most people can complete the installation in just a few minutes. Here are the installation steps:

- Clean the Pipe Ends

Wipe away any dirt, grease, or rust from both pipe ends. Ensure the pipe ends are smooth. - Position the Coupling

Slide the coupling onto one of the pipe ends. Align the second pipe with the first pipe. - Center the Coupling

Move the coupling so that it evenly covers both pipe ends. - Tighten the Clamp

Tighten the clamp using a screwdriver or torque wrench. Ensure the clamp is tightened securely and evenly. - Inspect the Seal

Check that the connection is properly sealed and the pipes are straight. Check all components before turning on the water valve.

Tip: The HWKG flexible connector can be installed without special tools. If needed, you can also remove and reuse it.

Many people prefer this connector because it saves time and effort and effectively prevents installation errors. Its design prevents leaks and allows for quick pipe repairs.

Choosing the Right Coupling

Selecting the best flexible PVC connector requires considering several factors. Different applications may require different sizes or types of connectors. Before purchasing or installing a connector, consider the following:

| Factor | Description |

|---|---|

| Compatibility | Ensure the connector is compatible with the pipe material (e.g., PVC, ABS, cast iron, or steel). |

| Pressure Ratings | Ensure the connector can withstand the system pressure, typically up to 150 psi for PVC pipes. |

| Temperature Ranges | Check that the connector operates within the appropriate temperature range, such as -20°F to 180°F. |

| Installation Practices | Follow the manufacturer’s instructions for installation to ensure a tight seal and prevent leaks. |

| Long-Term Durability | Consider sunlight, chemicals, and the long-term lifespan of the connector. |

| Code Compliance | Ensure the connector complies with local plumbing codes and standards. |

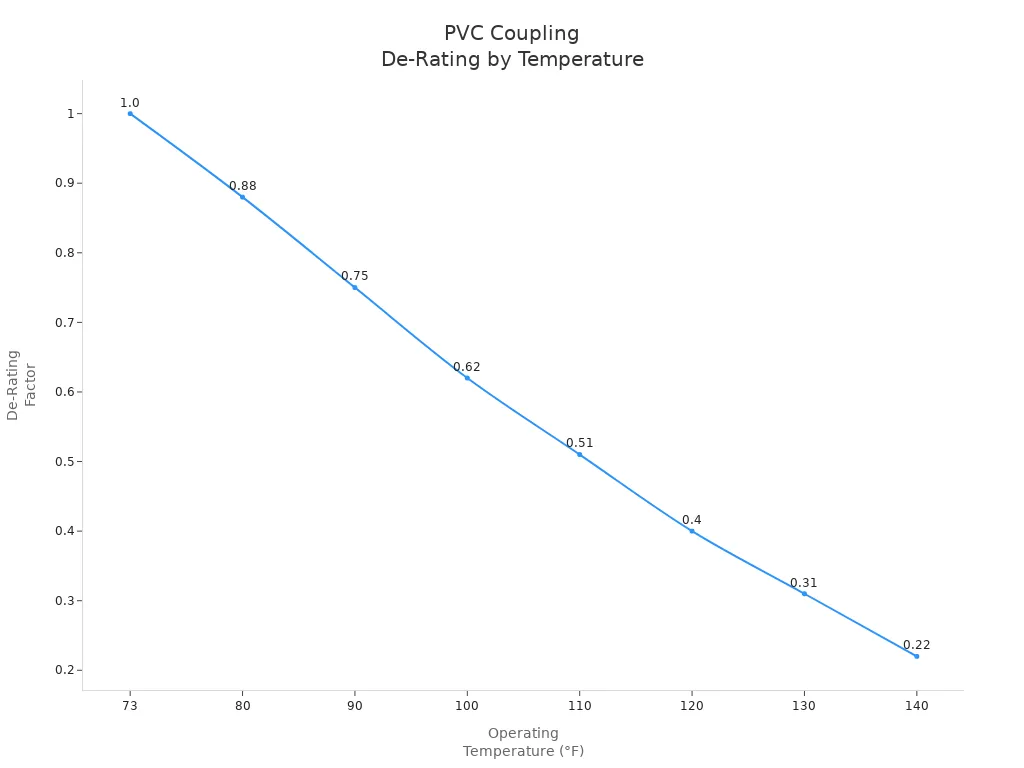

Temperature affects the performance of the connector. As temperature increases, the pressure rating decreases. The table below shows how the derating factor decreases with increasing temperature:

| Operating Temperature (°F) | De-Rating Factor |

|---|---|

| 73 | 1.00 |

| 80 | 0.88 |

| 90 | 0.75 |

| 100 | 0.62 |

| 110 | 0.51 |

| 120 | 0.40 |

| 130 | 0.31 |

| 140 | 0.22 |

Users should also check for chemical resistance and UV resistance, especially in outdoor or industrial environments. For irrigation systems, UV resistance and resistance to pressure surges are most important. In industrial settings, chemical safety and the use of clean materials are crucial. Always follow local regulations and safety standards, such as NEMA FB 2.20-2021, for best results.

HWKG manufactures robust and reliable pipe connectors. Their connectors effectively resist chemicals and sunlight and prevent leaks. The table below lists the main advantages:

| Feature | Benefit |

|---|---|

| Vibration damping | Keeps pipes safe from shaking |

| Watertight sealing | Stops water from leaking |

| Durability under pressure | Holds pipes together even when pushed |

Choose HWKG if you want a durable and reliable piping system.

FAQ

What types of pipes can HWKG flexible PVC connectors connect?

HWKG connectors can connect PVC, cast iron, steel, and copper pipes.

You can use these connectors in residential, industrial, and agricultural settings.

How long does installation take?

Most people can install HWKG connectors in just a few minutes.

- No special tools are required.

- These connectors can be disassembled and reused.

Are HWKG flexible PVC connectors suitable for outdoor use?

| Feature | Yes/No |

|---|---|

| UV Resistant | Yes |

| Chemical Safe | Yes |

| Leak Proof | Yes |